Bridge Plug

“EZ-HM” BRIDGE PLUG

Description

The TMOT EZ Bridge Plug is a Hydro-Mechanical (HM) Packer that is set by a combination of hydraulic pressure and mechanical pull, with setting tool being designed for a greater efficiency under high pressure situation.

The EZ Bridge Plug is a simple, economical, fully drillable, and conventional string run permanent bridge plug. It is also ideal for applications in which a wireline unit is not available or economical. The HM packer is available in two types:

- The economical 5000 psi version (EZ-5)

- The high performance 10000 psi version (EZ-10)

The EZ HM Plug may be run and set in tandem with retrievable production packers, or as service tools.

Features

- Settable in all Casing Grades

- Drillable Cast Iron Construction

- Metal Back-Up Rings to Prevent Rubber Extrusion

- Usable for both Temporary and Permanent Services

- Ratcheting Lock Ring Holds Setting Force

- Excellent for Deviated Wells due to Compact Assembly

- Designed to Eliminate risk of " Accidental” Set

- Large ID Through Setting Tool After Setting

- Extremely Simple Operation

“EZ DRILL SVB” SQUEEZE PACKER

Description

The TMOT "EZ Drill SVB Squeeze Packer" has a brass mandrel that is stronger and more ductile than cast-iron mandrel deployed in other packers.A s a result, the packer can absorb greater tensile and impact loads as well as higher internal pressures. The brass mandrel is drilled as easily as the cast iron mandrel.

The valve arrangement improves performance in high-temperature and high-pressure areas, especially when the valve is cycled repeatedly. The valve also performs well when it is cycled under conditions in which fluid cannot be held static, particularly when there is a pressure or a flow underneath. The slips of the EZ Drill SVB Squeeze Packer allow the packer to be set inside all casing grades up to V150

Features

- Controls Flow and Pressure Differential in both Directions.

- Allows Pressure-Testing of the Workstring.

- Runs-in Quickly.

- Sets inside a Wide Range of Casing Grades.

- Contains Rugged Brass Mandrel, Improved Slips, and Enhanced

- Sliding- Valve Seals.

- Can be Set on Electric Wireline, Slickline, Coiled Tubing, and Jointed Pipes.

- Can be Set Mechanically or Hydraulically.

“K1” CEMENT RETAINER

Description

The K1 Cement Retainer is a high-performance, drillable cement retainer which is ideal for most remedial cementing applications. The K1 was designed to function as a drillable squeeze packer that acts as a plug after cementing, which in turn traps squeeze pressure on the cement below the retainer and isolates the newly cemented area from the hydrostatic pressures above the cement retainer. This drillable cement retainer is available for most casing sizes and has a sliding valve arrangement for pressure containment. The tool can be set on wireline or threaded pipe. It has a two-way valve that is controlled from surface; no springs to cock or stick; just pick-up workstring to close and set-down to open the valve.

Features

- Can be set mechanically by tubing or drill pipe, or by wireline.

- Run-in speed is determined by the operator.

- Workstring can be tested before squeezing by picking-up to close the valve.

- Automatic valve closing when picking-up the workstring ensures

- lock-in of the squeeze under final pressure as excess cement is circulated out.

- Effectively isolates squeeze from hydrostatic pressure.

- New material specifications developed result in faster drill out.

“WL-BP” Wire Line Set Bridge Plug

Description

The TMOT Wire Line Set Bridge Plug (WL-BP) is a fully drillable, high performance permanent bridge plug suitable for zone abandonment or temporary suspension. It will safely handle working differential pressure up to 10,000 Psi. A one piece element, combined with full 360° coverage metal back up rings, provides a reliable seal for high pressure and high temperature applications up to 300° F. WL-BP is designed for speed and safety aspects while running on wireline, and for strength and durability after setting, high performance and reliability is not compromised in any way. This plug may be run and set using a standard "E-4 Wireline Setting Tool and Sleeve” with no special adapter equipment required. This Bridge Plug may also be run on tubing or endless tubing using a Hydraulic Setting Tool. If necessary, the TMOT "Wire Line Bridge Plug” may be run on tubing or coiled tubing.

Features

- Cost Competitive.

- Constructed from drillable materials.

- Retaining rings assist in preventing element extrusion.

- High temperature packing element is also available.

- Set inside hi-grade casing (P-110 & V-150 ...).

- Temperature rating 150 degrees Celsius/300 degrees Fahrenheit.

- Runs on existing wireline setting tool or hydraulic setting tools.

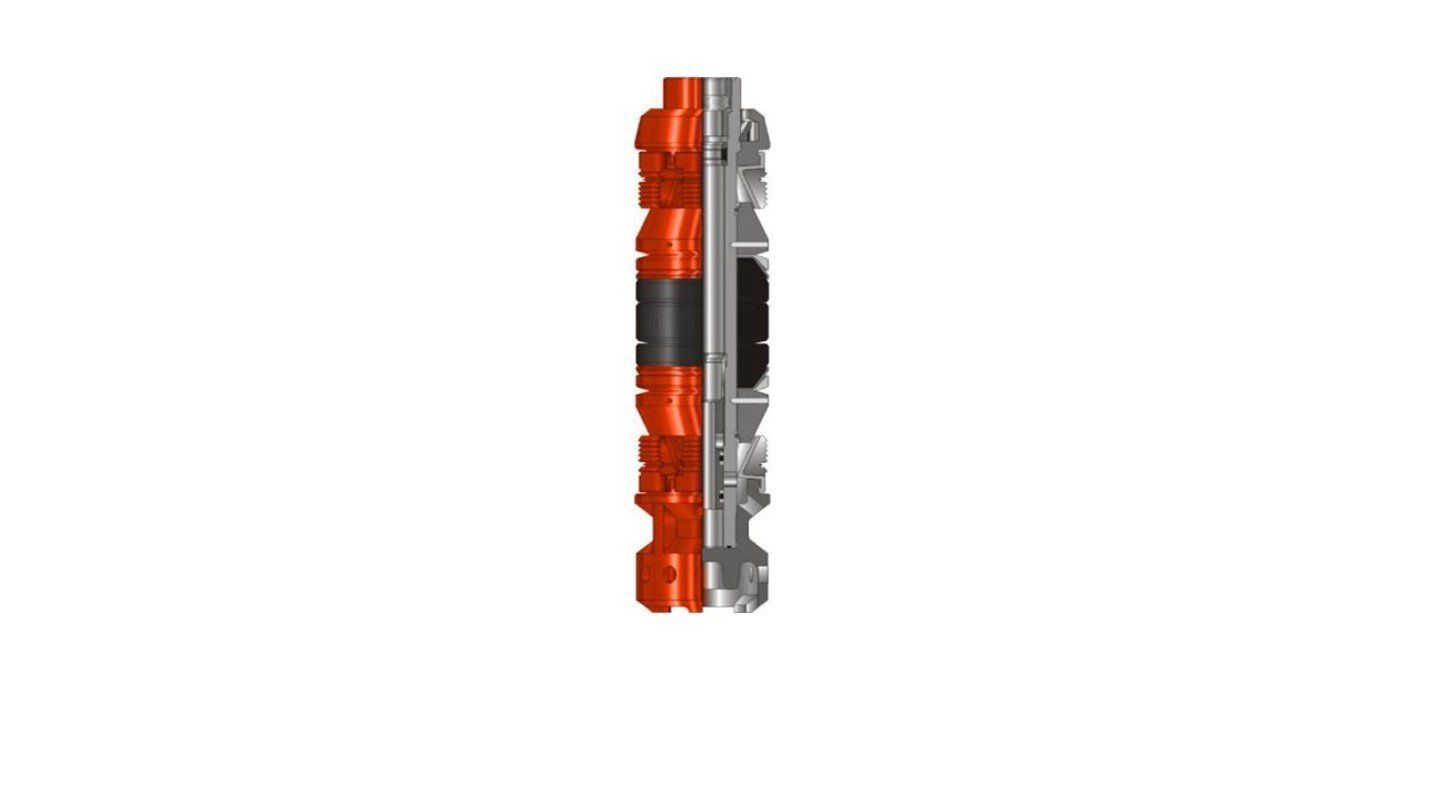

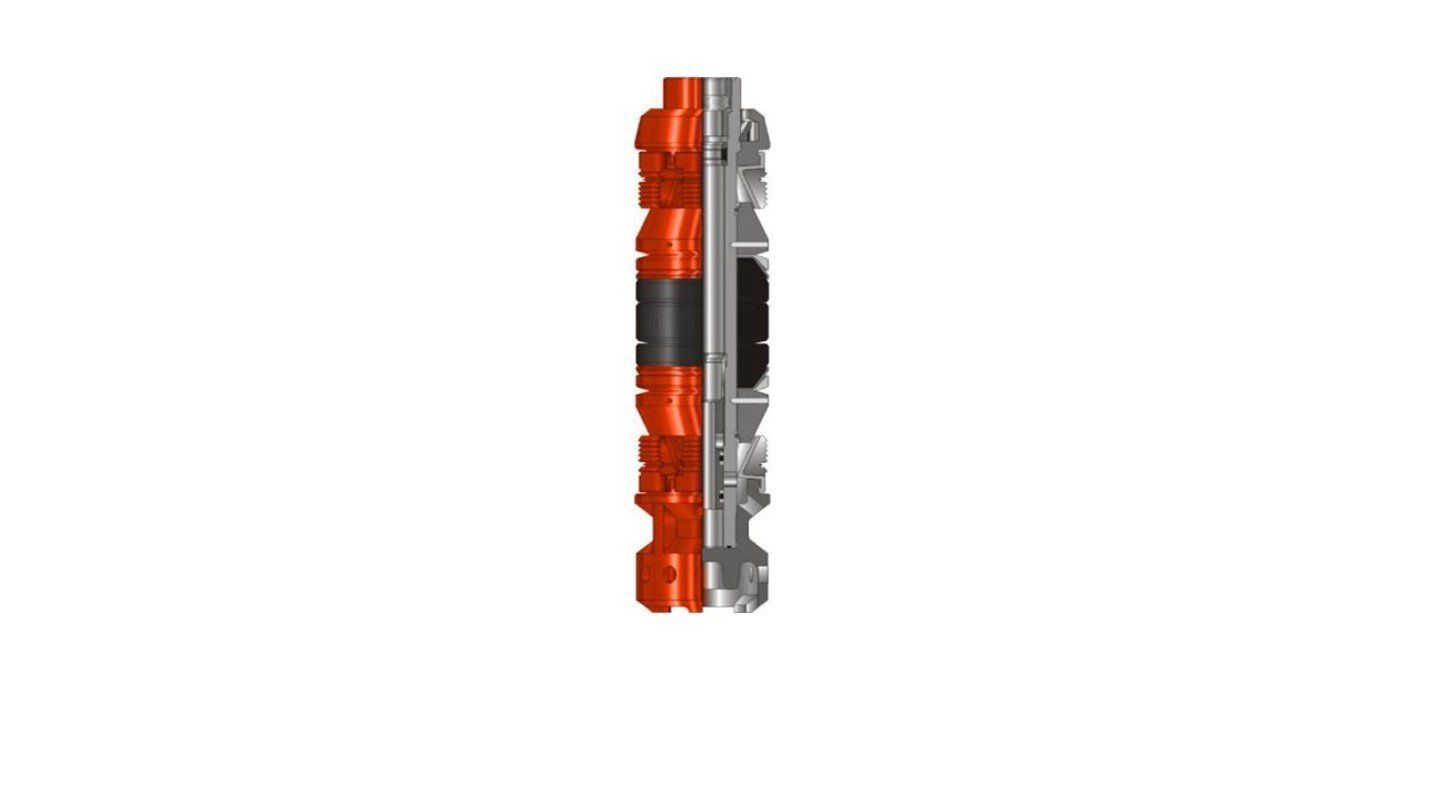

“TM-IRPP”INFLATABLE RETRIEVABLE PACKER

Description

The TMOT Inflatable Retrievable Production Packer (IRPP) is a high-performance inflatable packer that incorporates a high-expansion inflate element with a robust chassis for completion and remedial applications. The TM-IRPP can be used as a treatment packer or as a completion packer.

The TM-IRPP accepts other TMOT accessories making this tool suitable for a variety of applications, so it can be used to test tubing, casing, or liner integrity when deployed in conjunction with an existing plug in the wellbore or while TMOT bridge plug or Gravel-pack screens can be run below the TM-IRPP for sand control. In remedial pplications, it can be used to pump stimulation fluids, cement, or polymers for water control. Using a simple Bull Plug, turns the packer into a sophisticated Bridge Plug where no other plug can compete.

A variety of chemical resistant elastomer compounds suitable for temperature up to 350 °F are available. The inflatable packer elements are typically supplied with a standard elastomer compound which is suitable for temperatures up to 240 °F; high temperature compounds are available upon customer request. Long, 48”, elastomer seal lengths provide excellent anchoring capabilities while still maintaining a positive seal in open-hole or cased hole application.

Features

- High-performance inflation elements, capable of up to 3:1 expansion, make it ideal for high-expansion applications.

- Discontinuous rib design maximizes expansion ratio.

- Shallow square threads machined on mandrel (prevents element slipping during run-in).

- Only axial work-string movement is required to equalize and deflate the tool for retrieval; therefore, the tool can be run on coiled tubing.

- Strait-pull shear release facilitates retrieval on slickline, wireline, and coiled tubing.

- With a hydraulically activated inflation valve, the packer can be set without manipulation.