Liner Hanger

PRODUCTS

Description

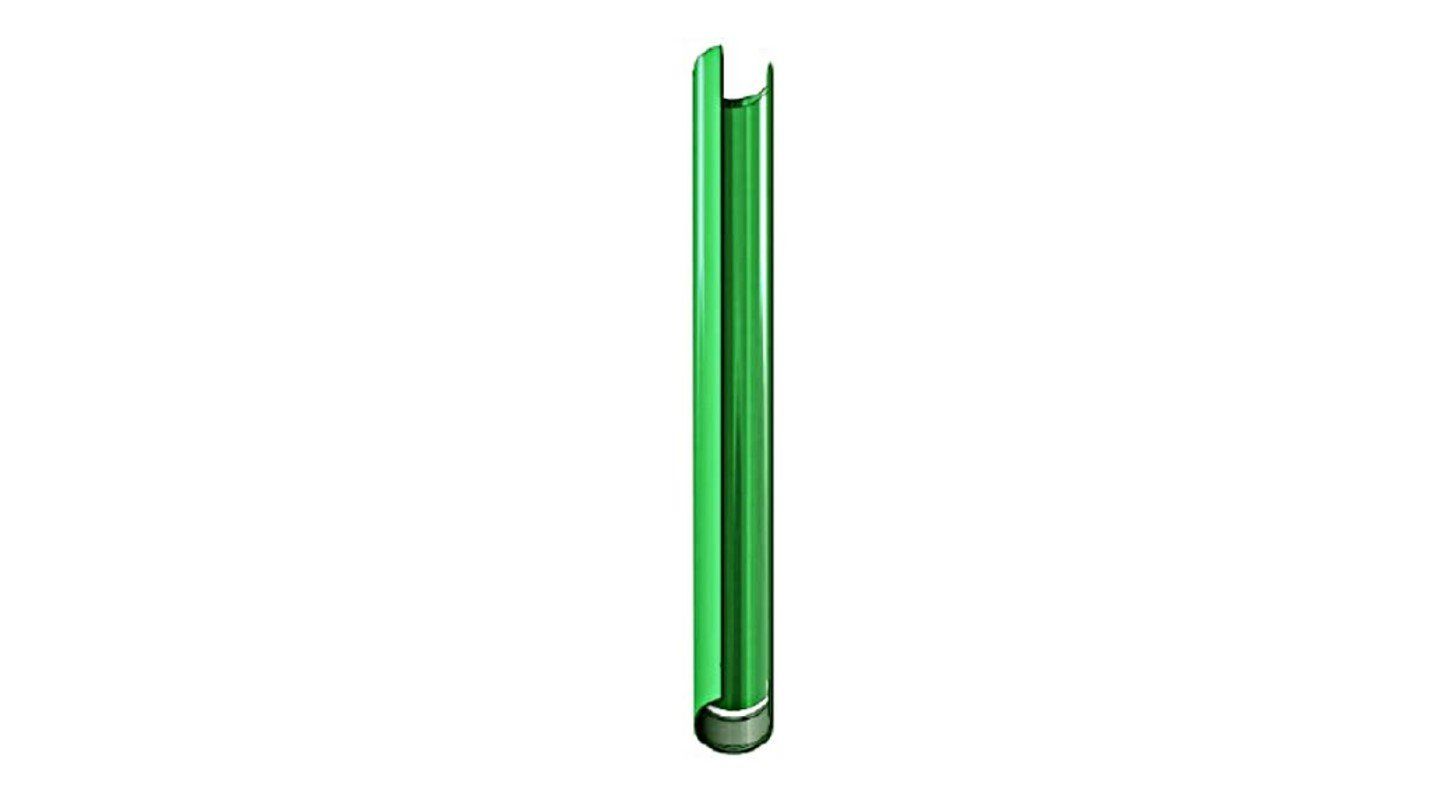

The Polished Bore Receptacle (PBR) is run as a part of the liner. This PBR comes as a means to tie-back to and existing liner with either a seal assemble or tie-back packer for remedial work. This PBR is a means to Tie-Back to the liner system should it be needed. This can be accomplished with a seal nipple or with a Tie-Back packer

Features:

- Honed ID reduces potential deal damage during stab-in operation

- Top guide bevel for easy seal entry Available in length of up to 30 feet without splice connections

- or con-centric couplings for optimal pressure integrity and seal performance

- L-80 and P-110 material grades are standard with other grades available by request

Description

Without the right LINER TOP PACKER in place and proper annular isolation, the integrity of your well is at risk, which can lead to costly and detrimental environmental and safety outcomes.

Liner-top packers are run as an integral part of liner-hanger assemblies to create a reliable liner-top seal between the host casing ID and liner string OD. Additionally, liner-top packers are used to isolate formation pressures below the liner top from the casing ID above, to isolate treating pressures below the liner top from casing or acid work, to isolate fluids while the cement sets, to eliminate gas migration, and to isolate lost circulation zones. Packers can also be used as a tieback completion or production packer.

Description

The HT hanger packer is used in high temperature non cement wells with low pressure (3000 psi) to provide a liner top seal. It is run as an integral part of the original liner string. Designed to be set after the liner is in place, the packer is set by pressuring up on the hydraulic pressure setting both by-direction slips and setting the high temperature ecnor aray element.

Features:

- Can be rotated during run-in

- Available with or without hold down slips and can be pulled if needed in heavy oil applications

- Optimizes chemical resistance to completion and production fluids with a variety of elastomer options for packer element and seal assemblies

- Maintains element setting with mandrel lock ring

- Facilitates high circulating rates with enhanced packer element de-sign without risk of element washout

- Anti swab while running or reciprocating allows to achieve high running speeds

- Eliminates extra components and connections with integral

PRODUCTS

Description

The LEJ is used in high temperature non cement wells with low pressure (3000 psi) to provide a liner the ability to expand or contract with temperature changes. The LEJ come in 10', 15' expansion lengths. Designed to be set below of the HT liner top packer

Features and Benefits:

- Can be rotated during run-in

- Optimizes chemical resistance to completion and production fluids with a variety of elastomer options

- Facilitates high circulating rates with enhanced packer element design without risk of element washout

- Eliminates extra components and connections

Description

The PS2 Liner Hanger is set by a pressure increase. A setting ball is dropped into a ball seat shear pinned in the setting tool liner wiper plug or the landing collar. The system is pressurized, at which point the piston moves upward, setting the slips into the casing wall. Slack off completes the setting action and transfers the liner weight through the cone and slips into the supporting casing. The PS2 Liner Hanger comes with an integral body. The PS-2 mandrel come with machined heavy wall mechanical tubing and is treated to its required grade. With no integral connections there are no maximum pressure ratings that can be exceeded. Hanging capacity of this hanger is rated best in the industry casing spec.

Features and Benefits:

- No reduction of annular by-pass of fluid past the slips in the set or unset position (Industry First)

- Dual Cone Pocket construction adds the highest hanging capacity in the industry

- Running speed of the PS-2 Dual Cone Hanger is greatly enhanced due to its recessed slip design

- The clutch drive of the setting collar allows for rotating of liner into the well bore and during cementing operations should that be re-quired

- The PS-2 Hydraulic Liner hanger can be manufactured in any grade of material and comes standard in L-80, 80,000 psi yield materials

- Comes with proprietary fully field adjustable non binding shear pin(Industry First)

- No internal connections with high pressure integrity

- Patent Pending proprietary external part body locks

Description

The MR liner rotating setting tool is designed to run all types of mechanical and hydraulic-set liner hangers. The MR tool uses left-hand threaded nut assembly, with a spring-loaded clutch that pre-vents rotation of the nut until the tool is compressed. With the tool in tension, right-hand torque may be applied to rotate a liner, and then weight is slacked off to allow right-hand release of the set-ting tool. It incorporates setting dogs to for setting a liner top packer.

Features and Benefits:

- Incorporates setting dogs assembly for setting liner top packer

- Bearing race is used to transfer additional weight in high angle well bores

- Short length (about 400 mm) for easy transportation and assembly

- Single piece mandrel for high integrity

- Single setting tool for many types of liner applications reducinging country inventory needs

- Easily maintained for part replacement when needed