Sandstop Expandable Screen (SES) System

Sandstop Expandable Screen (SES)

System Benefits

- Easy and safe installation.

- Is an expandable screen that can achieve borehole contact and eliminate the annulus without using a Gravel Pack.

- Provides 36% more filtration/flow area than other expandable screens on the market. (Lower skin factor)

- Stabilizes weak formations, allowing them to withstand high depletion.

- Reduced exposure to logistics and health, safety and environment risks during installation phase.

- Reduced costs during the installation phase.

- CasedAhole functionality, in particular compatibility with downhole flow control (DHFC).

- Zonal isolation capability, after SES deployment

- An alternative to Open Hole Gravel Pack (OHGP) completions.

- Higher wellhead pressure, comparing with other sand control solutions

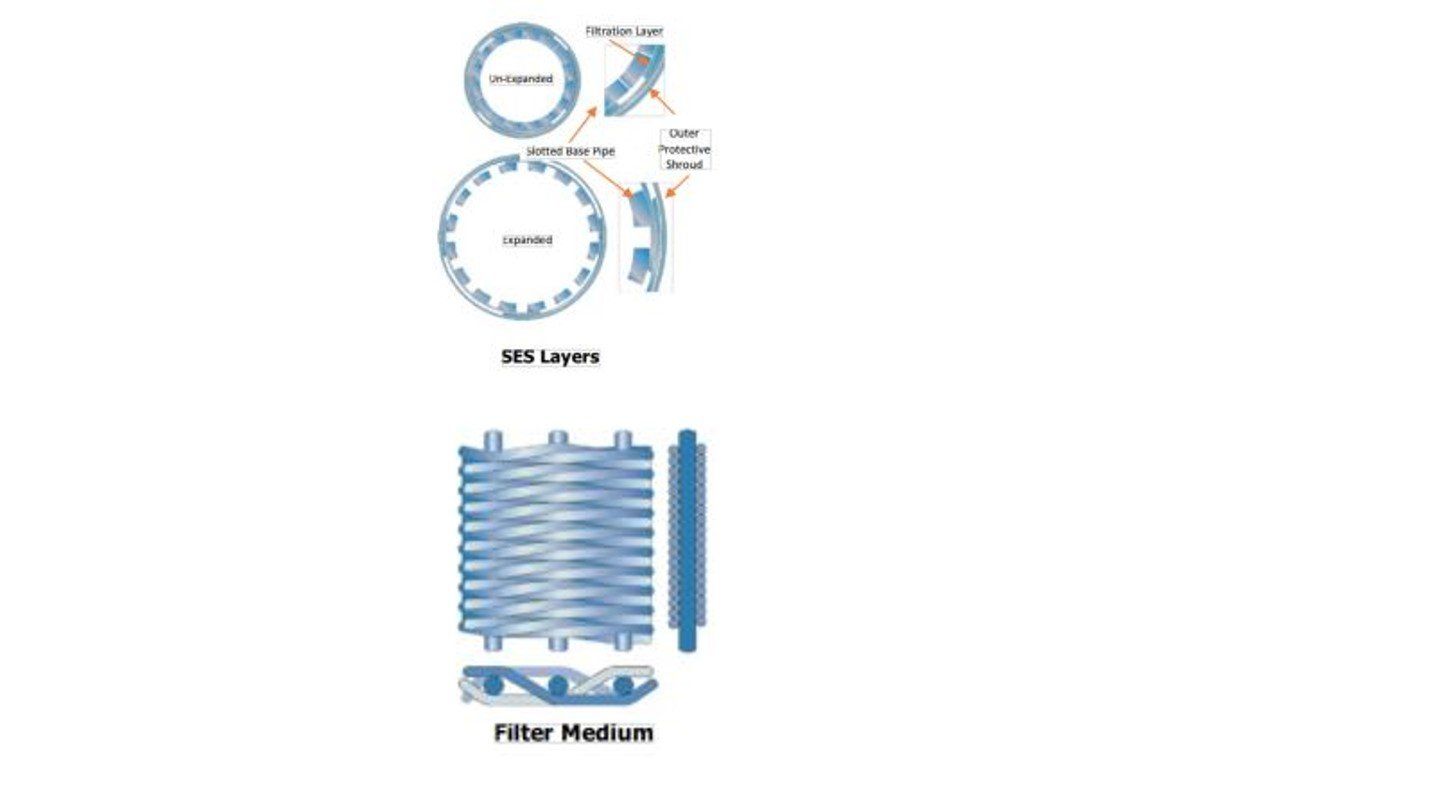

Construction

SES is a three-layer construction manufactured

to the highest standards, robust enough to

withstand the toughest well conditions while

maintaining sand exclusion for the life of the

well.

Slotted Base Pipe: The first layer of a SES

Screen Joint is the tubular stainless steel pipe,

slotted to an exact pattern and precise

specification using an automated abrasive high-pressure water jet slotting system.

Filtration Layer: Sand Control Filter Medium,

woven to a Dutch Twill design, sandwiched

between Slotted Base Pipe and Outer

Protective Shroud. The filter layers overlap each other along the length of the base pipe and slideto accommodate the circumference increase during expansion while remaining sand-tight.

Outer Protective Shroud: Pre-perforated

expandable plate formed around Filter Medium

and seam welded along the length of the SES

Screen Joint. The Outer Shroud protects the

Filter Medium during deployment. The three layers are held together using a special welding process to ensure strength and integrity.

SES Screen Joints

Description

The SES Screen Joints consists of slotted stainless steel tube, around which overlapping layers of filter membrane are attached. A final layer of pre-slotted stainless steel plate is then formed around the outside, keeping the filter membrane firmly sandwiched and protecting the filter media from damage during deployment. The Joints have integral slotted connections and because there are no “blank areas” each part of an SES Joint contributes to flow. Connections are designed to be sand tight, both pre and post expansion.

Components & Benefits

Components

- Slotted base pipe

- Dutch Twill wire mesh cloth filter media

- Perforated protective outer shroud

- Sand-tight expandable connection

Benefits

- mproved productivity

- Effective sand control solution

- Large ID in reservoir section, improved inflow performance

- Elimination of screen / hole annulus

- Borehole stabilization

- No blank sections at connections