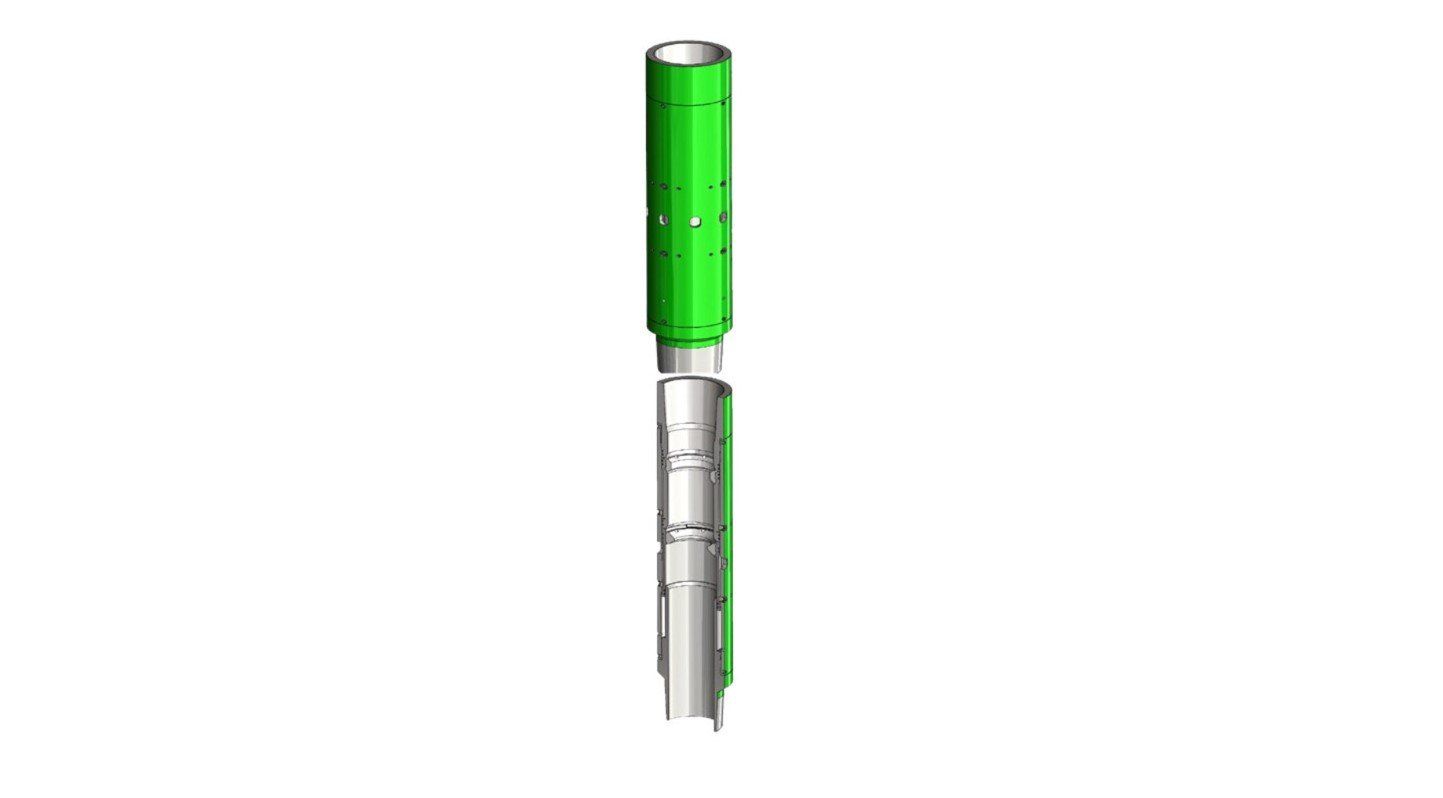

Stage Tool

TMOT stage-cementing systems provide cement integrity in wells that require selective zonal isolation. Two-stage cementing techniques are the most common of the multiple-stage cementing techniques, but a three-stage method can be used. They are the tools of choice when drilling requirements call for proven technology and low risk.

Multiple-stage cementing tools are recommended for the following circumstances:

- Wells where the hydrostatic head of the cement is greater than the formation

- pressure in some intervals but no other intervals

- Heavier-weight cement would be required in the high-pressure formation sections

- to maintain control of the well

- When only certain portions of the wellbore require zonal isolation

In downhole conditions that require different slurry blends to address unique challenges to each segment and achieve the intended zonal-isolation integrity