Underreamer

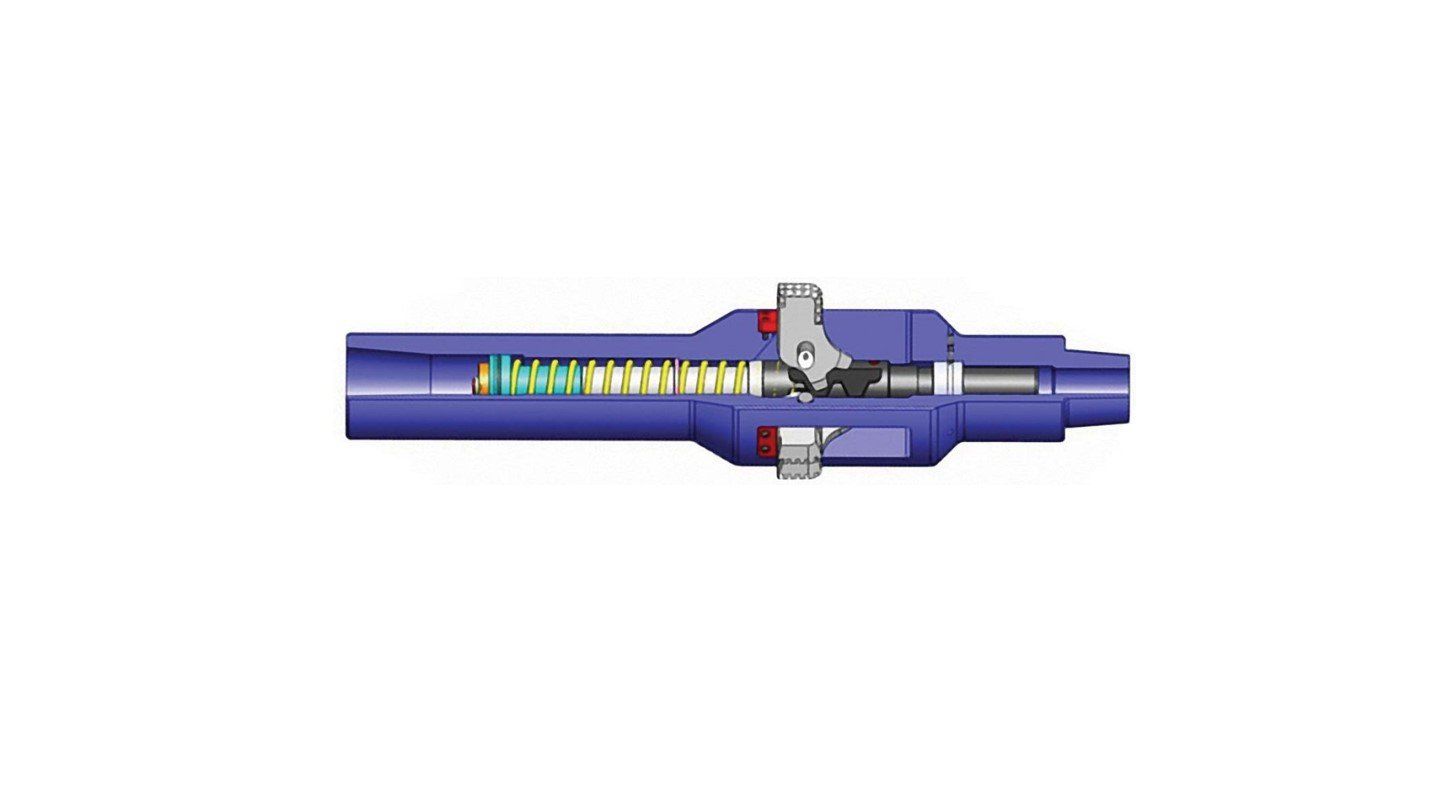

Techmaster Hydraulic PDC Underreamer is a hard wearing tool, used to enlarge the borehole beyond bit diameter. It can be opened and closed several times in downhole condition, making it the best choice for section enlarging jobs.

This simple and efficient arm design increases longevity and facilitates field maintenance.

The optimum mud ports placement also ensures thorough cleaning of the PDCs for faster reaming with less pack-off risks.