Whipstock

MasterWhipstock

Types

- Single Trip Hydraulic Set (Permanent or Retrievable).

- Single Trip Mechanical Set (Permanent or Retrievable).

- Single Trip Openhole (Expandable Anchor).

- Cement Type Openhole.

- Inflatable type Whipstock.

Existing production range available from 5” to 20”, other sizes are available based on client specific requirement.

Sections

- Whipface: A concave shaped bar located at the top portion of the whipstock and is used to deflect the mill outwards.

- Anchor: The anchoring section is the ottom portion of the whipstock and is used to secure the whipstock in place and is connected to whipface by hinge system.

- Milling system.

Features

- Field Proven anchor design. Whipface, hinge connectors and mills are available in various combinations to suit all applications.

- Mills are designed and dressed with Viper inserts and Tungsten Carbide for strength, optimum milling performance to minimize milling time, yet deliver optimum length and in-gauge window.

- The unique design of MasterWhipstock mills hook up provides protection of the shear mechanism from axial forces reducing the risk of premature shear while running in hole and facilitating ease of installation and reducing make up time due to the flexible design.

- Running tool for hydraulic actuation of the packer is a proven system used for many years.

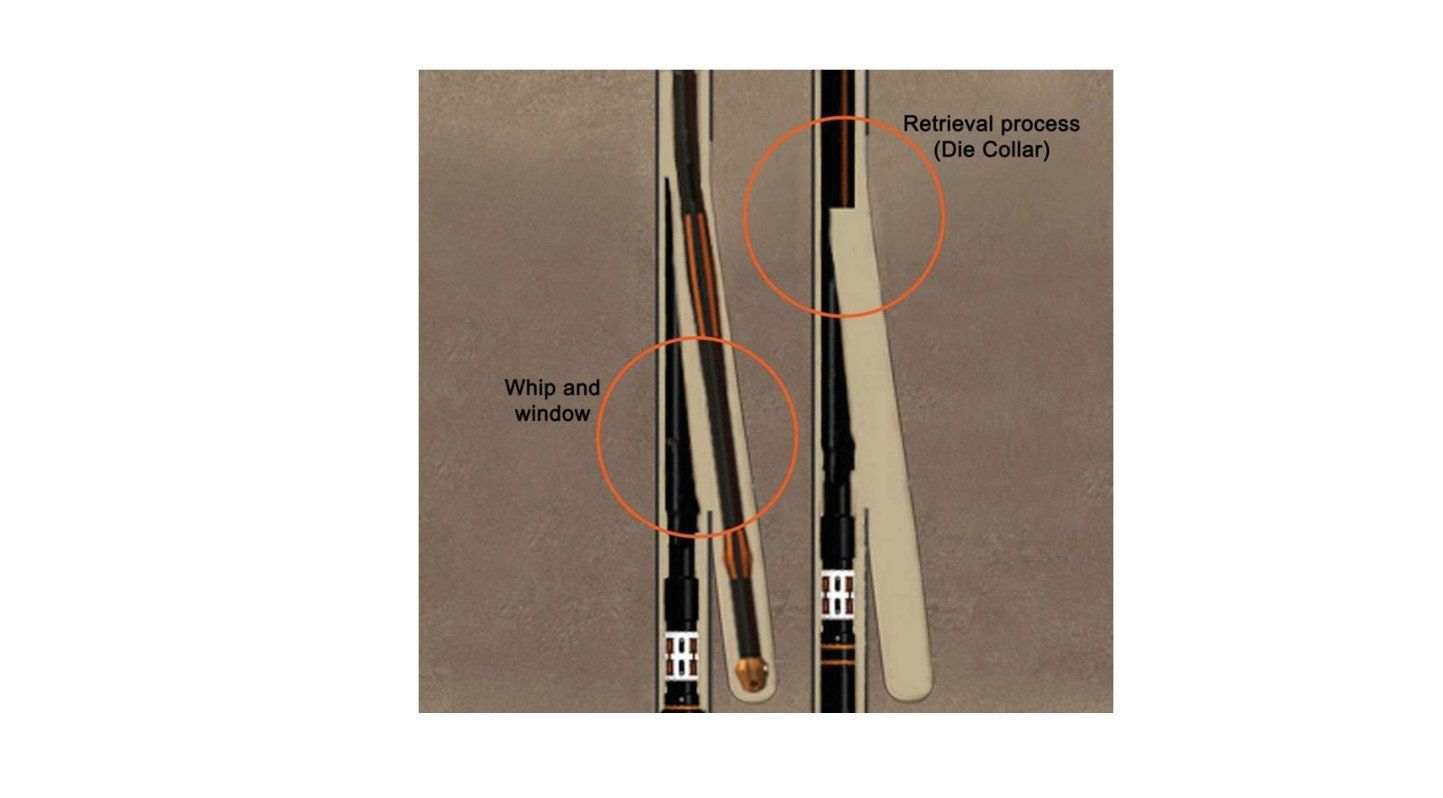

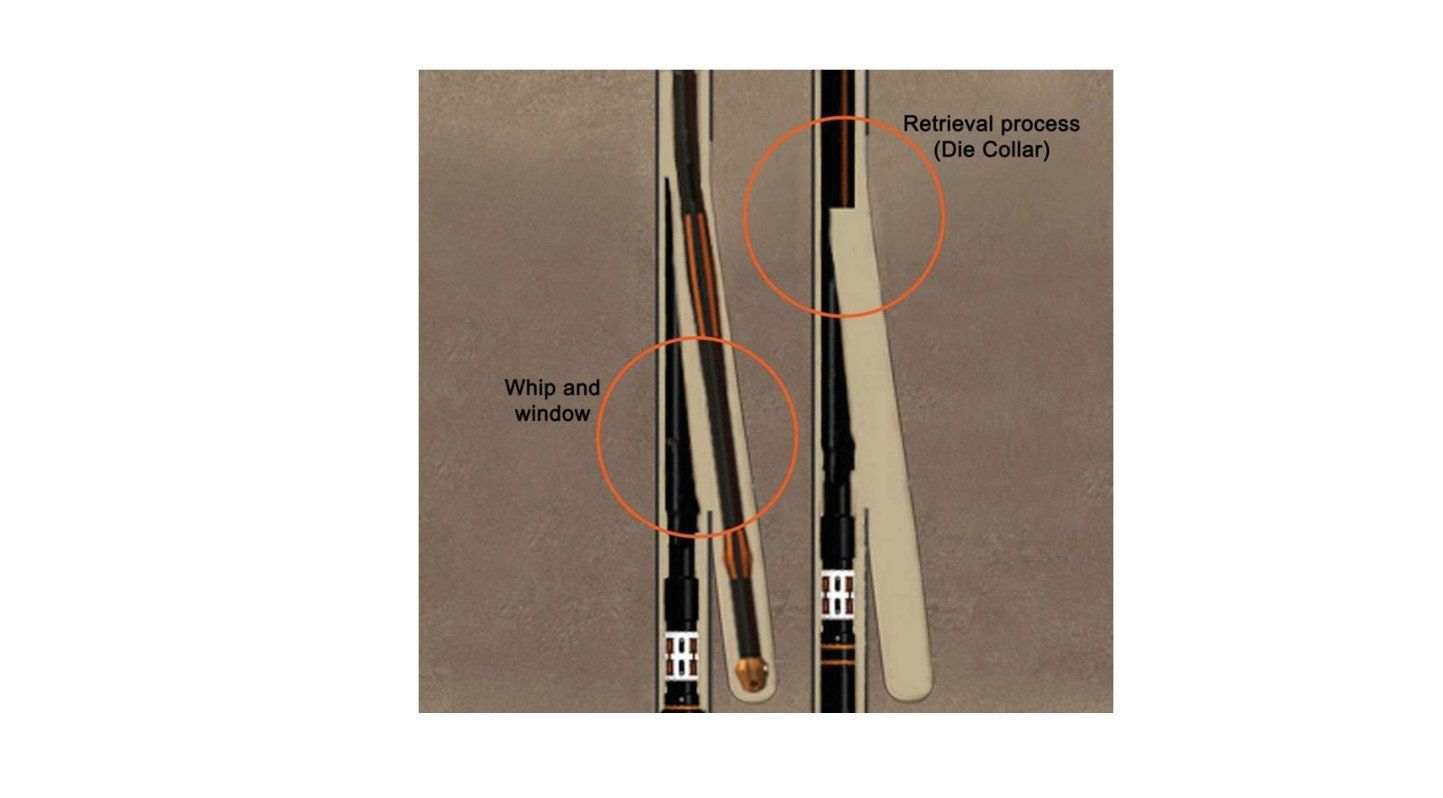

- The retrieval hook and die collar are designed for retrieving the whip/anchor systems.

- All parts are manufactured from high strength and heat treated materials to provide strengths and durability.

Whipface

Description

The whipface section is the part of the hipstock that actually directs the mills through the casing wall. MasterWhipstock’s Whipfaces have numbers of features, each of them having a specific function that contributes to the success of the whipstock operations

Features

- Masterwhipstock offers different Whipfaces with angles from °2 to o3

- The MasterWhipface has a special design to assist the mill to cut casing uniformly and rapidly without “coring” problems.

- A unique robust “hook-up” system protects the shear bolt from torsional and tensional forces during running allowing the whipstock / BHA to pivot relative from each other for maximum ease when installing in wells with restrictions or high dog leg sections.

- Design of the profile ensures deflection of the mills laterally towards casing wall for a rapid cut out of the window achieving maximum length and gauge ofthewindow.

- A retrieval slot is machined and located in whipface for retrieval by hook.

- Top section of whip body is machined to allow clearance and engagementwith die collars and overshots.

- Milled slot in the back to house hydraulic system and protect while running. anufactured to API / ASME standards and specifications.

Hydraulic Set Anchor Packer

Design Advantages & Benefits

The Hydraulic Set Anchor Packer is available from 5” to 8/3-13” sizes

- Available in Permanent and Retrievable type options.

- The Hydraulic packer features tetra-directional slips that resist both upward and downward movement of the whipstock. Also it resists in right and left directions and prevents rotation of packer after it is set.

- Low setting pressure required.

- Designed to maximize the amount of hydraulic force generated directly into the seal and retaining slips.

- Ratchet system locks slips and seal in position.

- Copper cup seals provide an interference seal, preventing rubber element from creeping.

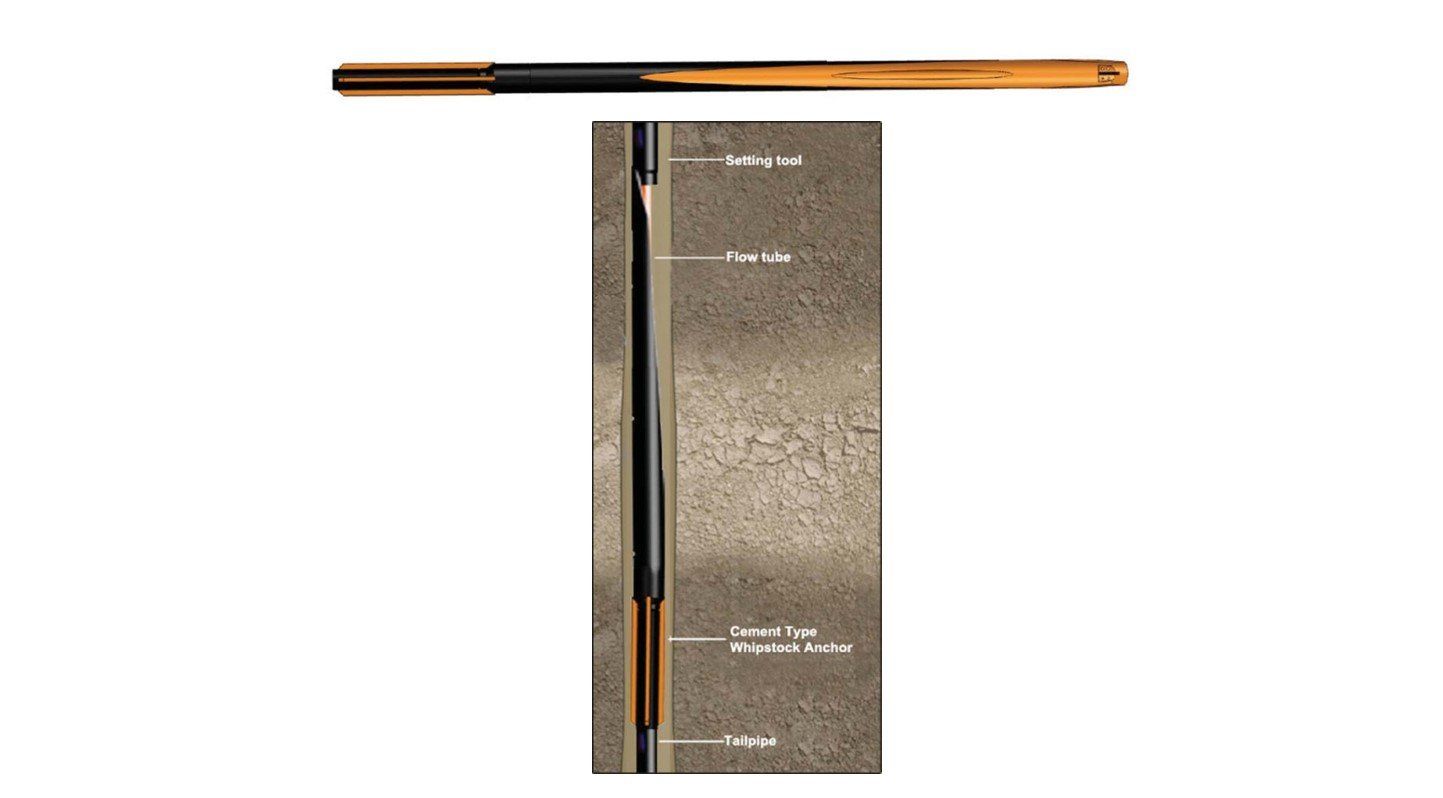

Mechanical Set Anchor

Description

Single Grip Model: The single grip mechanical anchor is designed to firmly anchor the whipstock within the cased wellbore to enable sidetrack operations. The anchor is run in place using drill string along with the whipstock and the mill, and is set by tagging the bottom of the hole, cement plug or liner top. The anchor can then be properly positioned by pulling it up in the hole to the desired setting depth. Compression is then applied to the drill string to set the anchor and shear the mill’s shear screw. The anchor can easily be retrieved by latching on the whipstock and applying tension to the drill string.

Double Grip Model: The double grip mechanical anchor features bi-directional slips that resist both upward and downward movements of the whipstock. Similar to the single grip tool, the double grip anchor also give positive centering of the whipstock within the casing when in the set position. This mechanical anchor allows the mill’s shear bolt to be sheared in tension or compression without movement of the anchor. The anchor can easily be converted from a permanent to a retrievable version in the field.

Openhole Whipstock

Description

Expandable Anchor Openhole Whipstock

The Expandable Anchor Openhole Whipstock is designed to be set in open hole, expanded the Anchor and set into position and drill out the window and rat hole in single trip. This type can be also cemented in place.

This Type of Whipstock is generally used to sidetrack in open hole when a hard formation will not allow the sidetracking. The Openhole Whipstock can be oriented with the use of orientation sub and survey equipment.

Advantages & Benefits

Advantages:

- Can be used with or without Cement.

- Positive kick-off point in hard formations.

- Ramp to build and maintain deviation in unconsolidated formations.

- Eliminates total reliance on cement integrity in areas where cement plugs are difficult to achieve.

Benefits:

- Single Trip System when not using cement.

- Potential savings in cement costing.

- Reliable in wide range offormations.

- Easy to set and side track.

- Cost savings in time waiting on cement and in time spent “time-drilling”.

- Reduces the need for multiple cement jobs.

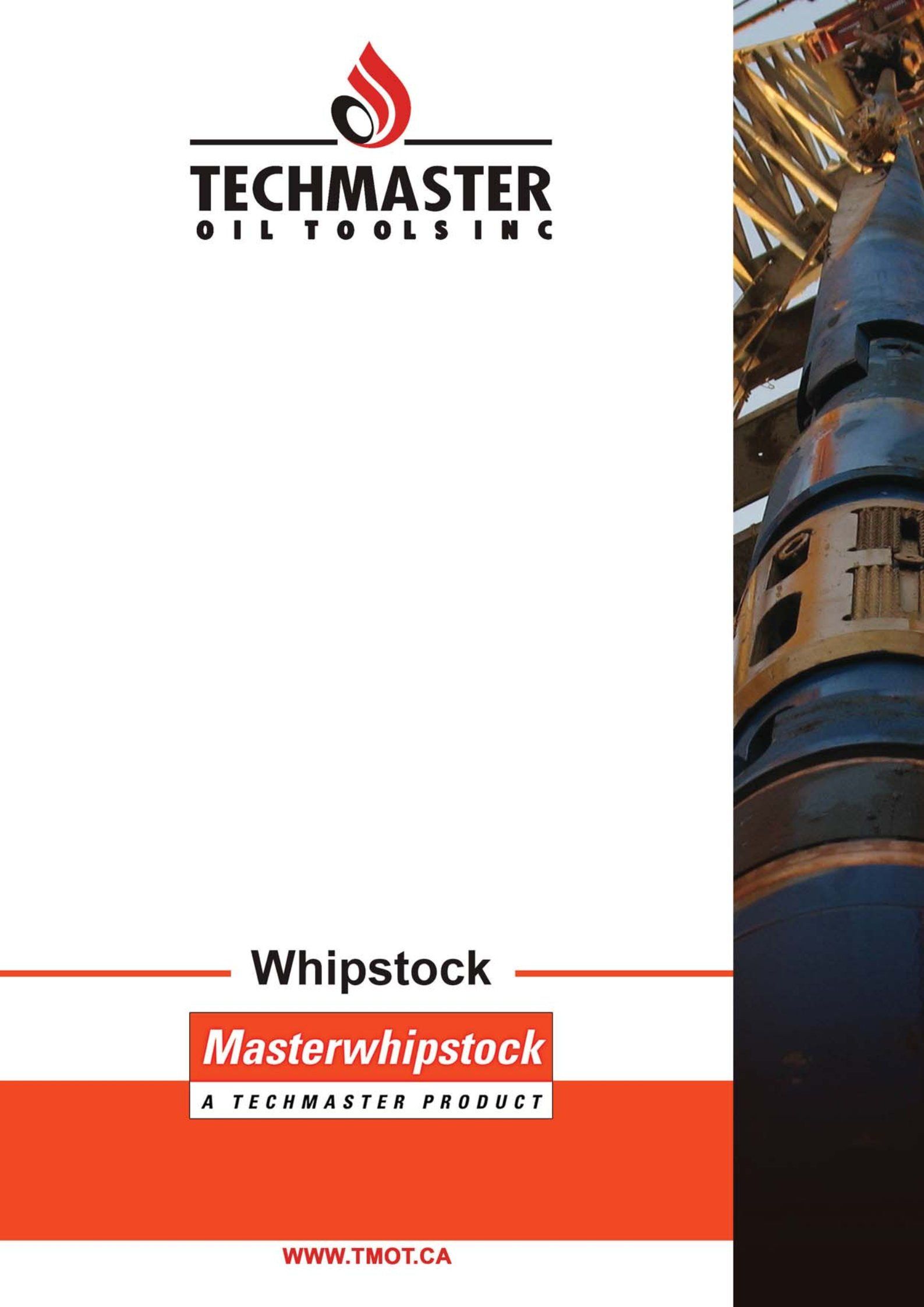

Cement Type Whipstock

Description

Cement is pumped from the surface through the drill string, setting tool and whipstock to the bottom of the whipstock. Once the cement reaches below the whipstock, the whipstock is then lowered, set inside the cement and then allowed to harden in place. After the cement is hard, a drill bit is used to continue drilling down the concave face ofthe whipstock

Benefits

- Positive kick-off point in hard formations.

- Ramp to build and maintain deviation in unconsolidated formations

Inflatable Openhole Whipstock

Description

The Inflatable Open Hole Whipstock Packer is used below a Whipstock Assembly to provide solid anchoring and support. In addition, the tool also provides zonal isolation in Openhole or in casing. Inflatable packer elements for these tools are 66 inches in length with 4 foot seal lengths. High strength aircraft cable is used to provide expansion characteristics in washed out or irregular well bores. Cable reinforcement allows these elements to return very close to the original run-in diameter.

Retrievable Whipstock

Description

Retrievable Whipstock is a specialized tool that can be deployed for multi-sidetracking in Openhole and opening multiple windows in cased hole.

Applications:

- Cost effective sidetracking.

- Avoids drilling new infill wells.

- Drill small rat holes for formation tests.

- Re-entry in exiting well.

- To drill multi-lateral well

Features

- Easily Retrievable.

- Mechanical and Hydraulic Set Models.

- Reliable in wide range offormations.

- Easy to set and side track.

- Reduces Cost and Time.

- Only One Trip Requires to Mill Casing Exit and Drill Pilot Hole.

- Integrity with MWD or Gyro for Orientation.

- Provides Low Dogleg Severity Across the Exit.

Hydraulic Running Tools

Design Advantages & Benefits

- Utilizes the proven piston type running tool.

- Clean oil reservoir promotes trouble free acting of hydraulic packers, separated by a reliable debris barrier

Hydraulic Running Tools

Design Advantages & Benefits

- Utilizes the proven piston type running tool.

- Clean oil reservoir promotes trouble free acting of hydraulic packers, separated by a reliable debris barrier