Completions Catalogue

Product Line Summary

Open Hole Reamer

The TMOT Open Hole Reamer is generally run in order to dress out the open hole before installing TMOT Multi-Stage Frac Systems™. The Reamer is a rigid heavy-duty one-piece tool with 2 sets of 12 opposing tungsten carbide capped spiraled blades with an OD close to hole tolerances in order to best prepare the wellbore ID properly before running tools.

- HEAVY DUTY ONE PIECE DESIGN

- 2 SETS OF 12 TUNGSTEN CARBIDE BLADES

- CLOSE OD TO OPEN HOLE TOLERANCE

RSB Latch Seal Assembly

The TMOT RSB Latch Seal Assembly is designed to be used with either the RSB or the RSB-1 Packer. The RSB seal assembly incorporates heavy-duty quadruple bonded seals and is ran on the tubing after the packer has been set. The latch mechanism engages automatically with set down weight and disengages with right-hand rotation while pulling tension.

PREVENTS BOTH UPWARD AND DOWNWARD MOVEMENT WHEN LATCHED

- HEAVY DUTY BONDED SEALS

- AVAILABLE WITH PREMIUM ELASTOMERS

- LARGE BORE ID

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

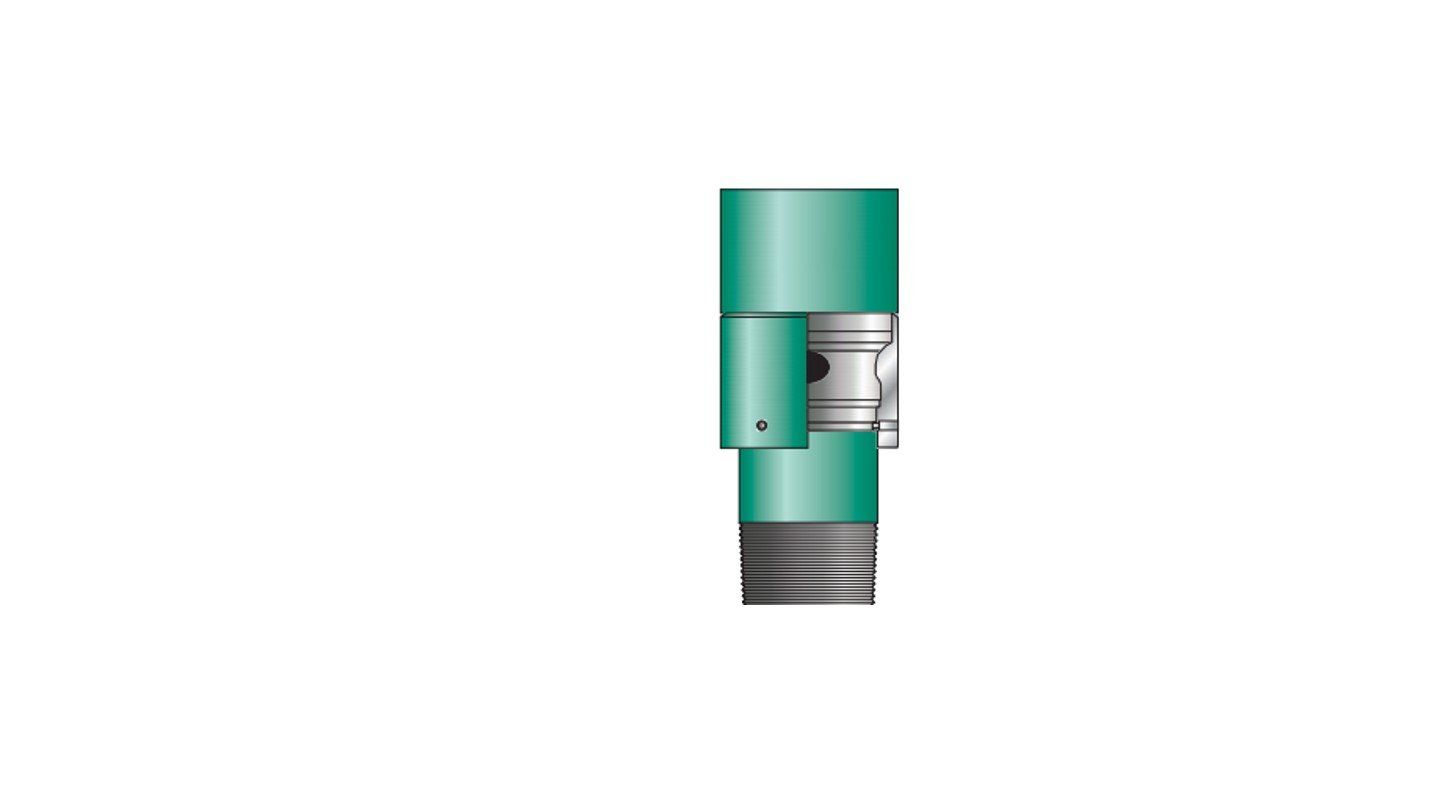

FZR On/Off Tool

The TMOT FZR On/Off is an overshot type tubing disconnect/connect incorporating a J-slot that automatically engages on and disengages with a % turn to the right at the tool. The FZR On/Off incorporates a proven and reliable quadruple bonded valve system which can be made out of various elastomeric materials as required. The FZR has a heavy-duty 3 lug J-slot design to maximize the tensile loading capability and a full bore slick joint that allows for the largest possible ID available while maintaining a high-pressure rating. A wireline profile can be cut in the slick joint if required.

- PROVEN BONDED SEAL SYSTEM

- RIGHT-HAND RELEASE/LEFT HAND RELEASE

- 3 LUG J-SLOT DESIGN FOR HIGH TENSILE LOADING

- FULL BORE ID

- WIRELINE PROFILE CAN BE CUT IF REQUIRED

- AVAILABLE IN A WIDE RANGE OF MATERIALS & CONNECTIONS

V-I/V-IIFRAC SLEEVE SYSTEM

The TMOT V-I/V-II Frac Sleeves are designed for selectively stimulating multiple zones in either vertical or horizontal wells. The V-I/V-II Frac Sleeves can either be run in conjunction with TMOT open hole packers or be cemented in the wellbore. As many sleeves as required can be run and each sleeve opens independently utilizing the TMOT V Actuation Tool on coil tubing. Using the Viking system, the frac can be pumped down the ID of the coil or the coil annulus.

- INTERNAL LOCKING MECHANISM

- FIELD ADJUSTABLE OPENING PRESSURE

- CAN BE USED IN CONJUNCTION WITH OPEN HOLE

- PACKERS OR CEMENTED IN PLACE

- DESIGNED FOR MULTIPLEZONE APPLICATIONS

- NO LIMIT ON THE NUMBER OF SLEEVES RAN

- ACTUATION TOOL UTILIZES SIMPLE DESIGN WITH HEAVY

- DUTY REINFORCED CUP FOR DURABILITY AND EFFICIENCY

- CAN BE PUMPED DOWN THE COIL ID OR COIL ANNULUS

- THE V-II IS THE CLOSEABLE VERSION

Product Line Summary

TMT Frac Tool

The TMT Frac Tool is designed for stimulating isolated zones wiTMIn cased vertical or horizontal wellbores utilizing coil tubing. Quicker running speeds can be achieved even when moving through fluid or live wells due to an innovative fluid bypass. When moving up-hole the valve shuts providing a closed system isolating the target zone and containing fluids/proppants from all previously stimulated lower zones. The top end of the TMT tool incorporates a coil tubing field adjustable shear release.

The TMT can be used in conjunction with the TMOT FB/CFB HydroPorts™ or any other similar frac port type systems such as other types of frac sleeves, burst disks or perforations.

- STIMULATION OF MULTI^ZONE WELLBORES - NEW & RECOMPLETIONS

- FUNCTIONS IN VERTICAL, DEVIATED, OR HORIZONTAL WELLS

- CAN BE USED WITH A WIDE RANGE OF FRAC PORT SYSTEMS

- RAPID DEPLOYMENT THROUGH FLUID FILLED WELLBORES

- SINGLE CUP ASSEMBLY AVAILABLE

- LARGE BORE

- FIELD ADJUSTABLE COIL TUBING SHEAR RELEASE

MASTERFRAC™-I PLUG

The TMOT MasterFrac™-! Plug is a high-pressure ball and seat plug designed to be used in plug and perf operations or other operations where multiple plugs are required. The MasterFrac™-I has a large bore ID and when the TMOT Dissolvable Balls are used, it isn’t necessary to drill the plug out. However, the plug incorporates only a compression slip making it readily retrievable if required.

- HIGH PRESSURE

- BOTTOM SET

- ENLARGE BORE ID

- NO NEED TO DRILL OUT

- SINGLE COMPRESSION SLIP ONLY

MASTERFRAC™-COMPOSITE PLUG

The TMOT MasterFrac-II™ Plug is a composite plug designed to be used for zone isolation for operations in both horizontal and vertical wells. The composite materials used in the plug allows for short drill time, which makes it ideal for multiple plug applications and coil tubing drill out. The TMOT MasterFracTM-II plug uses a composite material slip with hardened steel inserts on the lower slip and ceramic buttons on the upper slip for ease of drill out.

The MasterFracTM-II Plug can be set hydraulically or on wireline with the appropriate setting tool and adaptor kit.

- SETS SECURELY IN ANY HARDNESS CASING

- WIRELINE OR HYDRAULIC SET

- EASILY DRILLABLE COMPOSITE MATERIAL

- 70 mPa (10,000psi) RATING @ 135°C (275°F)

- CAN BE CONVERTED TO BE A SOLID BRIDGE PLUG

- ANTI-PRESET INCORPORATED IN PLUG

- DISSOLVABLE BALLS ARE AVAILABLE

TCP CUP PACKER

The TMOT TCP Cup Packer is available in a single or double cup design. The primary use is for isolating casing and tubing leaks. The packer cups can be installed in any direction allowing each assembly to hold pressure in both directions if required.

- AVAILABLE IN SINGLE OR DOUBLE ELEMENT DESIGN

- COMPACT & INEXPENSIVE MEANS OF ISOLATION

- WIRE REINFORCED CUPS FOR DURABILITY

Product Line Summary

Tension Packer

The TMOT Tension Packer is a compact, economical, retrievable packer. Primarily used in waterflood applications, TMIs packer can also be used for production and/or lower-medium pressure-treating

operations. Since the packer is tension set, it is ideally suited for shallow wells where set-down weight is not available. Various configurations of the TMOT Tension Packer are available including an endless J-slot version as well as alternate shear options.

- SIMPLE LOW-COST PACKER FOR FLUID INJECTION

- ENDLESS J-SLOT AVAILABLE

- ALTERNATIVE SHEAR RELEASE AVAILABLE

TM-3 SINGLE GRIP COMPRESSION PACKER

The TM-3 Single Grip Packer is a single-grip, compression-set, retrievable mechanical production packer that is suitable for most production, stimulation, and testing operations. The field-proven large bore design allows unrestricted fluid flow and wireline operations through the tubing. The TM-3 also incorporates an internal bypass to prevent swabbing when running and retrieving.

- NORMALLY RH COMPRESSION SET, STRAIGHT PICK-UP RELEASE

- OPTIONAL J-SLOT CONFIGURATIONS

- LARGE BYPASS FOR RUNNING, RETRIEVING AND EQUALIZING

- AVAILABLE WITH BOTH LONG AND SHORT STROKE MANDRELS

TM-4 DOUBLE GRIP COMPRESSION PACKER

The TMOT TM-4 Double Grip Compression Set Packer is used for production, stimulation, and testing. The mechanical upper hold-down system reduces the cost and maintenance of a button type hydraulic hold-down system. The TM-4 is equipped with a running bypass that reduces swabbing. Set down weight closes the bypass valve, sets the upper/lower slips and energizes the packing elements. The closed bypass valve activates the pressure balanced hold down system. Internal pressure from below the elements aids in holding the bypass valve closed and preventing upward movement of the tubing string.

To set, run the tool to setting depth, pick up tubing and rotate to the right % turn at the packer. Tubing weight is applied, which sets the lower slips, closes the bypass valve and expands the packing elements.

To release, raise the tubing, which first opens the bypass valve, then releases the slips and packing elements.

- NORMALLY RIGHT-HAND COMPRESSION SET, STRAIGHT PICK-UP RELEASE

- 4NO HYDRAULIC HOLD DOWN BUTTONS

- BUILT-IN UNLOADER WASHES DEBRIS FROM WHEN RETRIEVING

- SEQUENTIAL RELEASE UPPER SLIP SYSTEM

- AVAILABLE IN AUTOMATIC AND MANUAL JAY CONFIGURATIONS

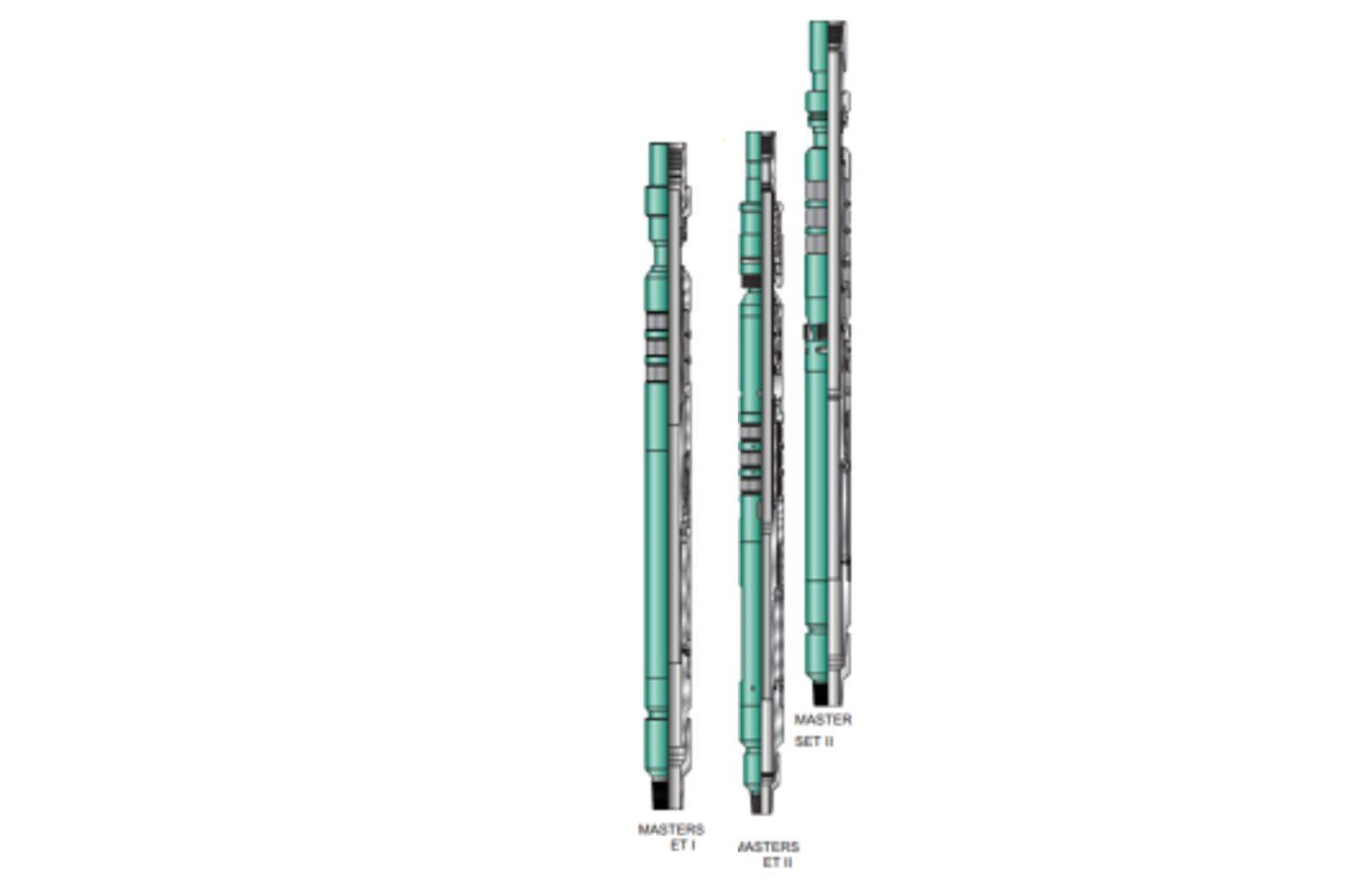

MASTERSET COMPRESSION SET ISOLATION PACKERS

The TMOT MasterSET Compression Set Isolation Packers are used in multi-zone completions. The MasterSET Packers set in compression with a lower anchor style packer below. The collet in the lower end of the tool shifts at a pre-determined value to energize the packing elements and set the upper slips. To release, straight pick-up on the tubing string is required.

The MasterSET I has no slips LEFT-HAND MasterSET II has a tension slip only and the MasterSET III has a compression slip only. The application and operational requirements will determine which is the best MasterSET to use.

- COMPENSATING PISTON HOLD DOWN SYSTEM

- RUNNING BYPASS/EQUALIZING SYSTEM

- KEYED FOR ROTATION THRU PACKER

- INTERNAL COLLET TO PREVENT PRE-SET

- SEQUENTIAL RELEASE SLIP SYSTEM

Product Line Summary

TMI HYDRAULIC ISOLATION PACKER

The TMOT TMI Hydraulic Isolation Packer is a hydraulic set, single string tandem packer used in multiple zone wells. The TMI Hydraulic Isolation Packer is generally used as the lower/middle packer(s) in multiple zone applications.

- ECONOMICAL

- EASILY ADJUSTABLE SET AND RELEASE SHEAR SCREWS

- COMPACT DESIGN

- CAN BE USED IN OPEN HOLE

HYDRO-TM PACKER

The TMOT Hydro-TM Packer can be run either on jointed pipe utilizing a conventional rig or rigless application using coil tubing. The Hydro-TM can be run alone or in tandem for testing, production, water shut-off or zonal isolation in either vertical or horizontal wells. The Hydro-TM is hydraulically set with an internal locking mechanism providing a positive and reliable long-term pack-off.

Both durable construction and compact size makes the Hydro-TM Packer an excellent alternative to conventional hydraulic packers in shallower wells. The Hydro-TM is released by dropping a ball onto an internal seat then pressure above causes the releasing pins to shear and the packer to release.

- INTERNAL LOCKING MECHANISM

- FIELD ADJUSTABLE SETTING PRESSURE

- FIELD ADJUSTABLE SHEAR RELEASE

- RELEASING MECHANISM INDEPENDENT OF SETTING MECHANISM

- CAN BE RAN IN SINGLE OR MULTIPLE PACKER APPLICATIONS

- CAN BE USED IN CONJUNCTION WITH OTHER COMPLETION TOOLS

- SUITED FOR BOTH VERTICAL AND HORIZONTALAPPLICATIONS

HYDRO-SET II HYDRAULIC SET PACKER

The TMOT Hydro-SET II hydraulic set packer is a compact 2 element single string pressure-activated double grip production packer, used in single or multi-zone completions. The Hydro-SET II Packer is ideally suited for applications where it is desired to set the packer(s) after the well is flanged up or for multiple zone completions. The Hydro-SET II Packer incorporates a pressure balance system that helps compensate for pressure differentials across the packer. The 2 element cup type system is a more compact packer in comparison to the Hydro-SET II.

- RUNNING BYPASS

- RELEASE EQUALIZING SYSTEM

- PRESSURE BALANCED SYSTEM

- STRAIGHT PULL RELEASE

- FIELD ADJUSTABLE SETTING PRESSURE

- FIELD ADJUSTABLE RELEASING SHEAR

HYDRO-SET III HYDRAULIC SET PACKER

The TMOT Hydro-SET III hydraulic set packer is a 3 element single string pressure-activated double grip production packer used in single or multi-zone completions. The Hydro-SET III Packer is ideally suited for applications where it is desired to set the packer(s) after the well is flanged up or for multiple zone completions. The Hydro-SET III Packer incorporates a pressure balance system that helps compensate for pressure differentials across the packer.

- RUNNING BYPASS

- RELEASE EQUALIZING SYSTEM

- PRESSURE BALANCED SYSTEM

- STRAIGHT PULL RELEASE

- FIELD ADJUSTABLE SETTING PRESSURE

- FIELD ADJUSTABLE RELEASING SHEAR

Product Line Summary

TM-2 DUAL STRING PRODUCTION PACKER

The TM-2 Dual String Packer is a hydraulic set, mechanically held dual string production packer run above a single string hydraulic set or wireline set seal bore packer. Its short length makes it ideal for deviated wells or doglegs. Because no tubing manipulation is required to set TMIs packer, the wellhead can be installed and flanged up before setting. It is available with short string or long string setting capabilities and a variety of tubing connections. It is also adaptable for submersible pump applications. The TM-2 features a sequential upper slip release system designed to release each slip individually reducing the pull required to release the packer. Due to the angles on the upper slips and upper slip cage, slips release smoothly from the casing.

TM-6/TM-6W DOUBLE GRIP RETRIEVABLE PACKER

The TMOT TM-6/TM-6W are lower pressure single string double grip retrievable production packers that hold pressure from above and below. Once set, the TM- 6/TM-6W can be left in tension, compression or neutral. Incorporated into the design is an internal bypass system that along with fluid bypass while running, equalizes pressure before the upper slips are pulled from the casing wall. The TM- 6/TX-6W Packers are designed for production, testing, zone isolation and injection applications.

The TM-6 sets with a 1/4 right hand turn at the packer and releases with a ¼ right-hand turn, then straight pick up. The TM-6W sets on wireline and releases with a 1/4 right hand turn at the packer then straight pick-up. The TM-6 can be re-set multiple times whereby once the TM-6W is released it cannot be re-set in the standard configuration.

- TUBING, WIRELINE OR HYDRAULIC SET ON TUBING

- CAN BE PACKED -OFF WITH EITHER TENSION OR COMPRESSION

- QUARTER TURN TO RIGHT TO SET AND RELEASE

- OPTIONAL LH J-SLOT AVAILABLE

- COMPATIBLE WITH A WIDE VARIETY OF TMOT PACKER ACCESSORIES

- THERMAL VERSION AVAILABLE

TM-8/TM-8WDOUBLE GRIP RETRIEVABLE PACKER

The TMOT TM-8/TM-8W packers are medium pressure single string double grip retrievable production packers that are capable of being set in tension or compression. Once set, the tubing string can be left in tension, compression or neutral. Incorporated into the design is an internal bypass system that along with fluid bypass while running, equalizes pressure before the upper slips are pulled from the casing wall. The Packers are designed for stimulation, service operations, production, testing, zone isolation, and injection applications.

- TUBING, WIRELINE OR HYDRAULIC SET ON TUBING

- CAN BE PACKED-OFF WITH EITHER TENSION OR COMPRESSION

- OPEN J-SLOT DESIGN

- 1/4 RIGHT HAND TURN TO SET AND RELEASE

- OPTIONAL LH J-SLOT AVAILABLE

- SEQUENTIAL RELEASE UPPER SLIP SYSTEM

- COMPATIBLE WITH A WIDE VARIETY OF PACKER ACCESSORIES

- SOUR SERVICE VERSION AVAILABLE

- AVAILABLE WITH PREMIUM ELASTOMERS

- THERMAL VERSION AVAILABLE

TM-10/TM-10WDOUBLE GRIP RETRIEVABLE PACKER

The TMOT TM-10/TM-10W are high-pressure single string double grip retrievable production packers that hold pressure from above and below. once set, the TM-10/TM-10W can be left in tension, compression or neutral. Incorporated into the design is an internal bypass system that along with fluid bypass while running, equalizes pressure before the upper slips are pulled from the casing wall. The Packers are designed for stimulation, service operations, production, testing, zone isolation and injection applications.

- TUBING, WIRELINE OR HYDRAULIC SET ON TUBING

- CAN BE PACKED -OFF WITH EITHER TENSION OR COMPRESSION

- OPEN J-SLOT DESIGN

- OPTIONAL LH J-SLOT AVAILABLE

- LARGE INTERNAL BYPASS

- SEQUENTIAL RELEASE UPPER SLIP SYSTEM

- TUBING CAN BE LEFT IN TENSION, COMPRESSION OR NEUTRAL

- COMPATIBLE WITH A WIDE VARIETY OF TMOT PACKER ACCESSORIES - AVAILABLE WITH PREMIUM ELASTOMERS

- THERMAL VERSION AVAILABLE

Product Line Summary

PERMAPAC PERMANENT SEAL BORE PACKER

The TMOT PermaPac Permanent Seal Bore Packer is a large bore, versatile permanent packer that can be used for single or multiple zone completions. It is ideally suited for HPHT and hostile environment applications as it can be readily manufactured out of several alternative material configurations. The PermaPac can be used for virtually any completion or production operation and can be converted into a temporary bridge plug by using a knock-out, pump-out or hydraulic disconnect bottom assembly.

The PermaPac Seal Bore Packer utilizes TMOT PermaPac seal bore accessories to make the tubing seal as well as other options.

- WIRELINE OR HYDRAULIC SET

- COMPONENTS KEYED FOR MILLING

- LARGE SEAL BORE

- CAN BE MADE WITH VARIOUS METALLURGIES AND ELASTOMERS

- CUSTOMIZED TO SUIT APPLICATIONS INCLUDING HPHT ENVIRONMENTS UP TO 260°C/500°F

PERMAPAC LATCH SEAL ASSEMBLIES

The TMOT PermaPac Latch Seal Assemblies are used for applications in which it is desirable to land the tubing in tension, compression or neutral or where an on/off connector, PBR or other similar devices may be used.

The seal assembly is latched into the packer with set down weight and released with right-hand rotation while holding tension in the string. For use with all models of seal bore packers and typically comes with a bottom lead in sub.

- SEAL CONFIGURATIONS CUSTOMIZED TO SUIT APPLICATIONS INCLUDING HPHT ENVIRONMENTS UP TO 260°C / 500°F

- CHEVRON OR BONDED SEALS AVAILABLE

- SEAL MATERIALS AVAILABLE INCLUDE NITRILE, HNBR, AFLAS, RYTON, VITON, CHEMRAZ, KALREZ AND TEFLON

PERMAPAC LOCATOR SEAL ASSEMBLIES

The TMOT PermaPac Locator Seal Assemblies are used for applications in which seal movement is necessary due to tubing contraction or in multiple packer applications. The locator seal assemblies may be combined with spacer seal units, spacer tubes, seal units and barrier seals to make up a longer seal assembly if required for use with a seal bore extension, a PBR or a retrievable seal bore packer.

For use with all models of seal bore packers and typically comes with a bottom lead in sub.

PERMAPAC SEAL UNITS

PermaPac Seal Units are designed so that the combination of seal units with spacer tubes and debris barriers are utilized as required in a seal bore completion design in order to ensure seal integrity is not compromised.

The Seals can either be bonded or 'vee' seal design and are available in various materials.

Product Line Summary

PERMAPAC SEAL SPACER TUBE

PermaPac Seal Spacer Tubes are used to lengthen seal assemblies if required. Spacer tubes are available in various lengths and are available for all seal assembly sizes.

PERMAPAC SEAL BORE EXTENSION

PermaPac Seal Bore Extensions are used to provide sufficient seal bore length so long seal assemblies may be used to accommodate tubing movement. The seal bore extensions are available for all sizes of PermaPac packers.

Seal Bore Extensions standard lengths are 1.5 m (5 ft) and 3 m (10 ft) lengths. Other lengths may be available if required.

PERMAPAC TUBING ADAPTERS/CONCENTRIC COUPLINGS

PermaPac Tubing Adapters are used to allow the connection of tailpipe directly to the bottom of the packer or seal bore extension. Tubing adapters are available for all seal assemblies and compatible tubing connections.

PermaPac Concentric Couplings are used to join to compatible sized seal bores to ensure proper alignment when running the seal assembly.

The Concentric Coupling is available for all seal bore sizes.

RSB/RSB-1 RETRIEVABLE SEAL BORE PACKER

The RSB/RSB-1 Retrievable Seal Bore packer incorporates the large bore benefits of a seal bore packer with the option of retrievability. The RSB/RSB-1 can be run for virtually all applications and can be used in applications whereby liner tailpipe assemblies are required. All load-bearing parts are designed to withstand large tension loads which makes it ideal for both vertical and horizontal applications whereby a liner system is to be anchored in place. The bi-directional slip system prevents both upward and downward movement after the tool is set. The RSB/RSB-1 does not rely on setting string weight or tension on it as it is set completely with differential hydraulic pressure or with a wireline setting tool.

The RSB-1 has both a lower and upper seal bore in order to maximize the ID through the connected tubingstring. The RSB/RSB-1 Packer is generally run on the ‘RSB’ hydraulic setting tool but can be set on wireline if required. The packer is set hydraulically by applying a field adjustable pre-determined tubing differential pressure against a plugging device below the tool such as a pump-out plug, a wireline plug or dropping/circulating a ball from surface to a ball seat sub within the setting tool.

Once set, the RSB/RSB-1 has an internal locking mechanism to ensure the setting tool remains set until it is desired to be released. The RSB Packer has a straight pull field adjustable shearrelease.

The RSB/RSB-1 packers utilize TMOT PermaPac seal bore accessories to make the tubing seal as well as other options.

- DESIGNED FOR BOTH VERTICAL AND HORIZONTAL APPLICATIONS

- INCORPORATES A BI-DIRECTIONAL SLIP SYSTEM

- AVAILABLE WITH CARBIDE SLIPS

- UPPER AND/OR LOWER SEAL BORES AVAILABLE

- INTERNAL LOCKING MECHANISM

- FIELD ADJUSTABLESETTING PRESSURE

- FIELD ADJUSTABLE SHEAR RELEASE

- CAN BE SET HYDRAULICALLY OR ON WIRELINE

- VARIOUS MATERIALS AND CONNECTIONS AVAILABLE

Product Line Summary

TX/TXN LANDING NIPPLES

The TMOT TX/TXN Landing Nipples are utilized in the completion string to allow for the positive location of numerous subsurface flow control devices such as blanking plugs, bottom hole chokes, downhole recorders, etc. The TX/TXN locking profiles allow for full selectivity in running flow control devices in completion strings where numerous profile nipples may be required. The TX profiles do not have a No-Go ring machined in the bottom of the nipple whereas the TXN does. Typically the No-Go nipple is the bottom profile in the string.

- VERSATILITY WHEN NUMEROUS PROFILES ARE REQUIRED

- LARGE BORE WHERE MINIMUM RESTRICTION IS REQUIRED

- SIMPLE, PROVEN DESIGN

- WIDE RANGE OF MATERIALS AVAILABLE

- WIDE RANGE OF SIZES AND CONNECTIONS AVAILABLE

TOR/TORN LANDING NIPPLES

The TMOT TOR/TORN Landing Nipples are utilized in the completion string to allow for the positive location of numerous subsurface flow control devices such as blanking plugs, bottom hole chokes, downhole recorders, etc. The TOR/TORN locking profiles allow for full selectivity in running flow control devices in completion strings where numerous profile nipples may be required.

The TOR profiles do not have a No-Go ring machined in the bottom of the nipple whereas the TORN does. Typically the No-Go nipple is the bottom profile in the string. Generally, the TOR/TORN profile nipples are used in higher pressure applications or those where smaller nipple sizes are required.

- VERSATILITY WHEN NUMEROUS PROFILES ARE REQUIRED

- LARGE BORE WHERE MINIMUM RESTRICTION IS REQUIRED

- SIMPLE, PROVEN DESIGN

- WIDE RANGE OF MATERIALS AVAILABLE

- WIDE RANGE OF SIZES AND CONNECTIONS AVAILABLE

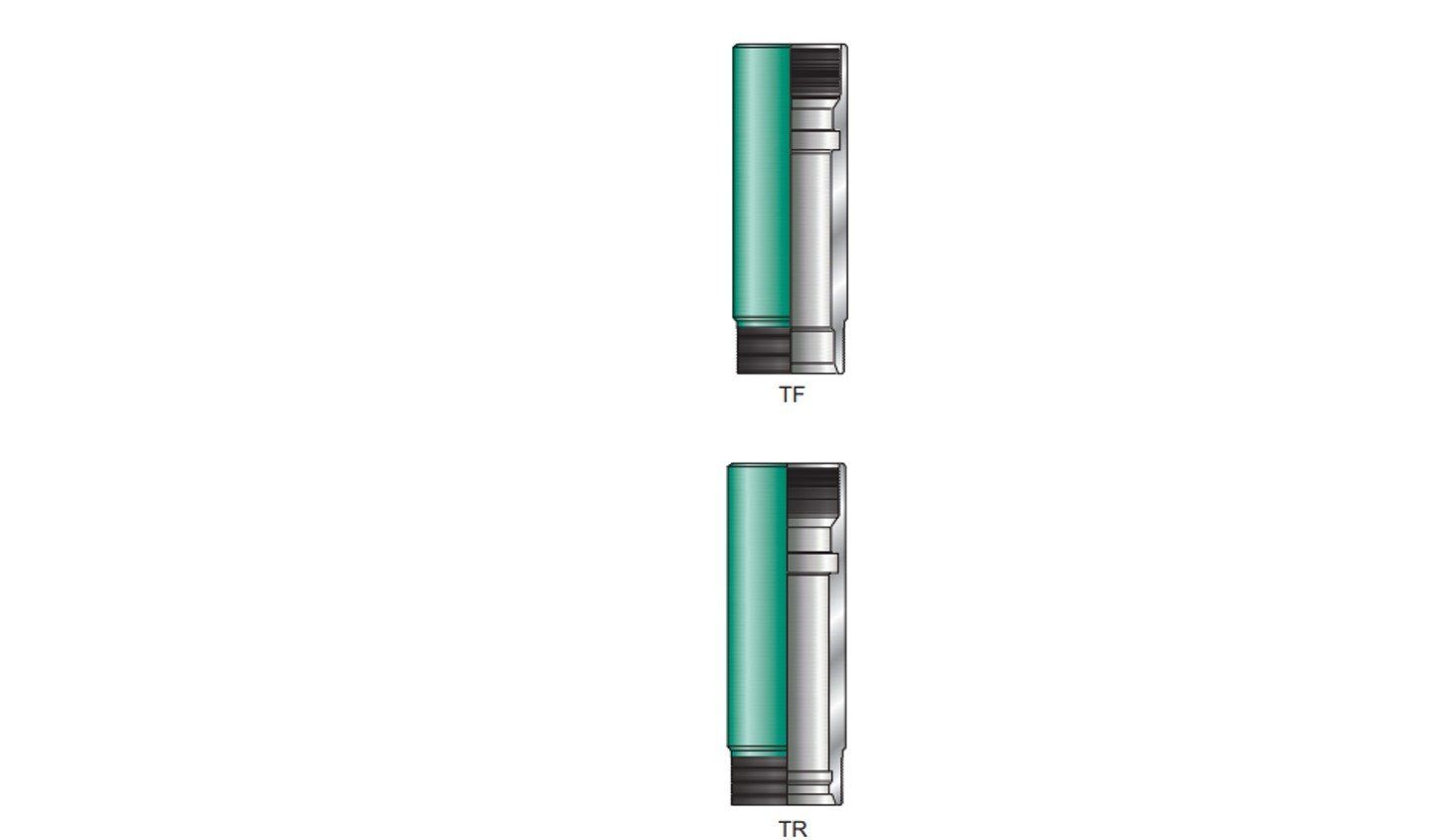

TF/TR LANDING NIPPLES

The TMOT TF/TR Landing Nipples are utilized in the completion string to allow for the positive location of various subsurface flow control devices such as blanking plugs, bottom hole chokes, downhole recorders, etc. The TF/TR Landing Nipples come in a wide range of profile sizes for each tubing size accommodating those applications where numerous profile nipples may be required.

The TF profile does not have a No-Go ring machined in the bottom of the nipple whereas the TR does. Typically the No-Go nipple is the bottom profile in the string.

- VERSATILITY WHEN NUMEROUS PROFILES ARE REQUIRED

- SIMPLE, PROVEN DESIGN

- WIDE RANGE OF MATERIALS AVAILABLE

- WIDE RANGE OF SIZES AND CONNECTIONS AVAILABLE

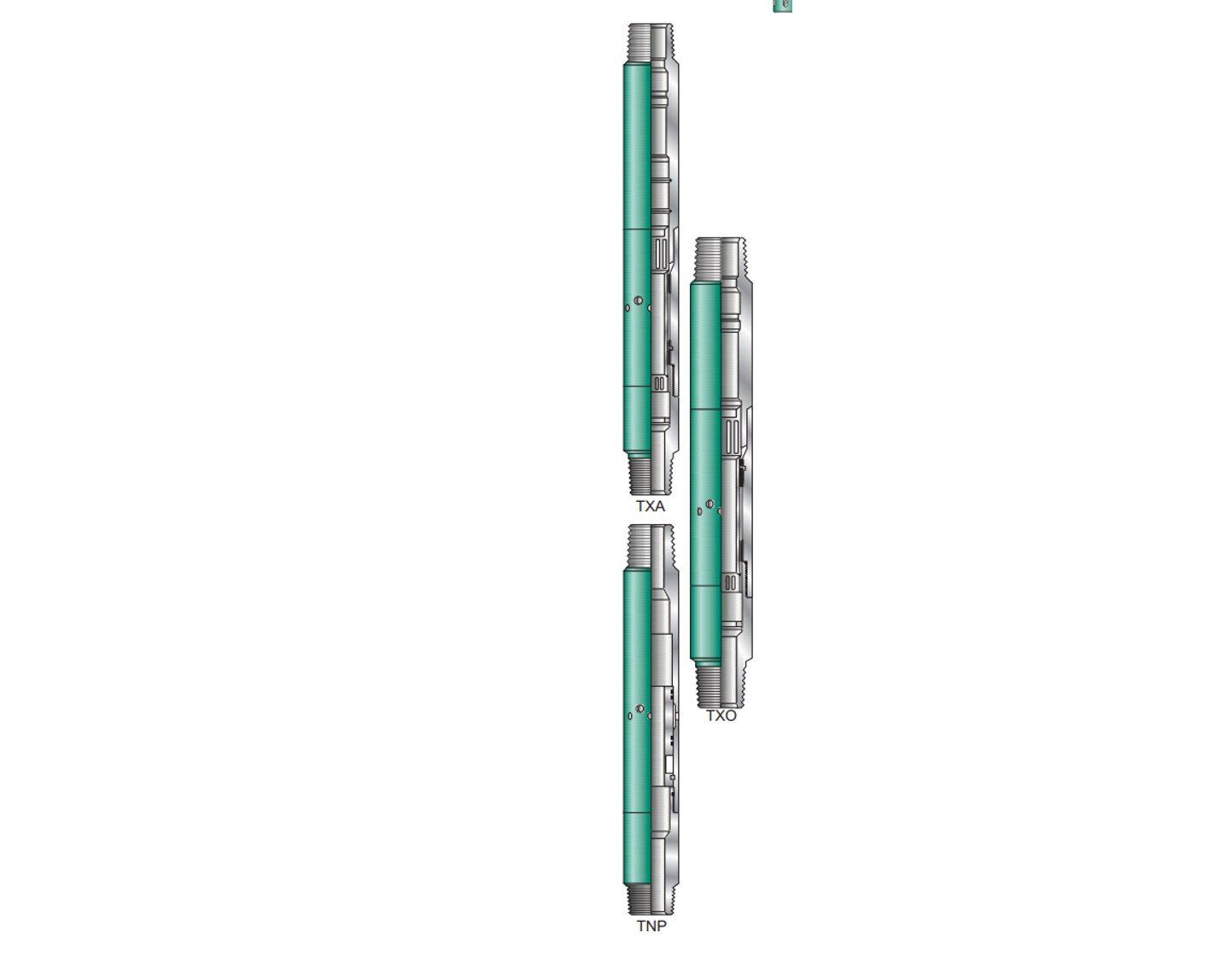

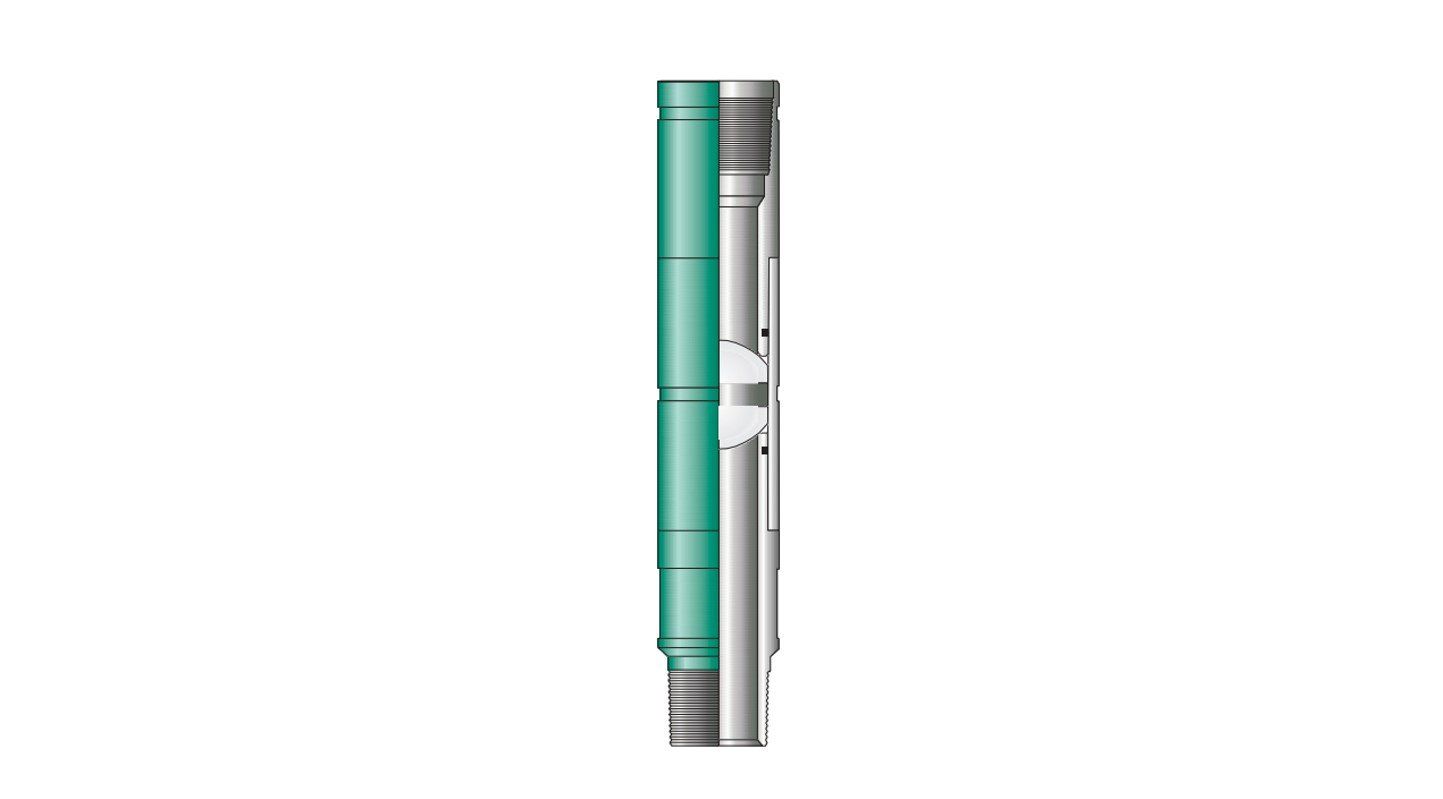

TXA/TXO/TNP SLIDING SLEEVES

The TMOT TXA/TXO/TNP Sliding Sleeves are full opening devices that are an integral part of the completion string, incorporating an inner shiftable sleeve which can be opened or closed using standard wireline/coil tubing deployed equipment and methods. All of the sleeves are designed such that the circulation/flow area is at least equal to the tubing size it is designed for. The standard sleeves incorporate the proven ‘vee’ seal design and can be varied to suit the environment and/or the application it is to be used in. The TXA and TXO both have landing profiles machined into the upper portion of the sleeve whereby the TNP does not.

The TXA and TNP shift upwards to open and the TXO shifts downward to open. All the sleeves use a standard ‘B’ shifting tool. The sleeves are designed so that normal wireline, coil or other operations will not open or close the sleeves inadvertently. Equalizing ports in the inner sleeve allows for equalizing when shifting the sleeve open in high-pressure differential applications.

- RELIABLE PROVEN DESIGN

- CAN BE SHIFTED MULTIPLE TIMES

- PORTED AREA IS EQUAL TO THE TUBING AREA

- EQUALIZING PORTS IN THE INNER SLEEVE

- AVAILABLE IN A WIDE RANGE OF MATERIALS

- WIDE RANGE OF SIZES AND CONNECTIONS

- TNP HAS FULL BORE ID

Product Line Summary

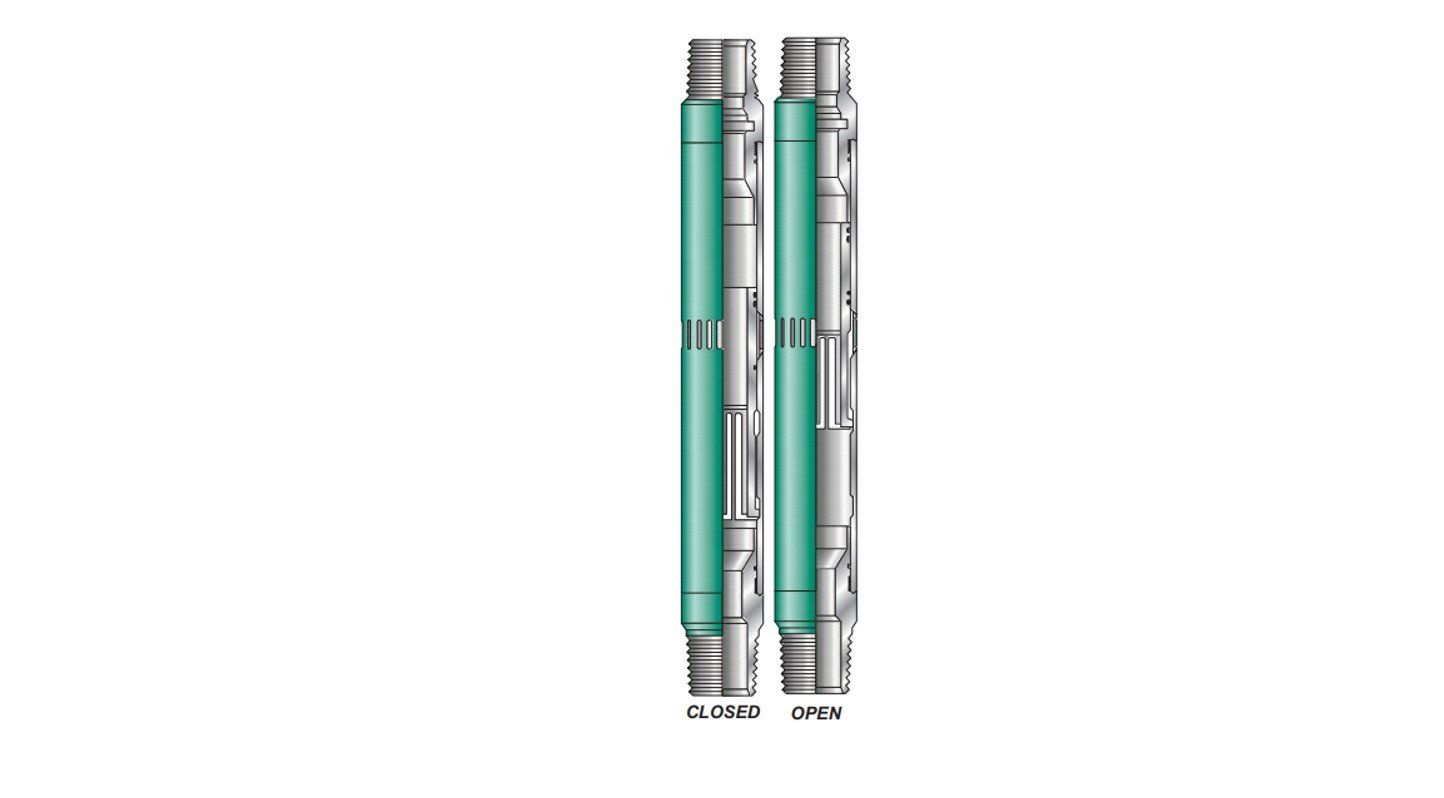

TM SLIDINGSLEEVE

The TMOT TM sliding Sleeves are full opening devices that are an integral part of the completion string, incorporating an inner shiftable sleeve which can be opened or closed using standard wireline/coil tubing deployed equipment and methods. The sleeve has bonded seals to ensure the integrity of the seals for the extended periods of time downhole. They can be of various elastomer types.

The upper sub has a selective TF landing nipple profile machined into it to allow for the proper shifting of the sleeve and to serve as a receptacle for various flow control devices. A standard D-2 Shifting Tool is used to shift the TM sliding Sleeve open and closed. The sleeves are designed so that normal wireline, coil or other operations will not open or close the sleeves inadvertently.

Equalizing ports in the inner sleeve allows for equalizing when shifting the sleeve open in high-pressure differential applications.

- RELIABLE PROVEN DESIGN

- CAN BE SHIFTED MULTIPLE TIMES

- SPORTED AREA IS EQUAL TO THE TUBING AREA

- EQUALIZING PORTS IN THE INNER SLEEVE

- AVAILABLE IN A WIDE RANGE OF MATERIALS

- WIDE RANGE OF SIZES AND CONNECTIONS

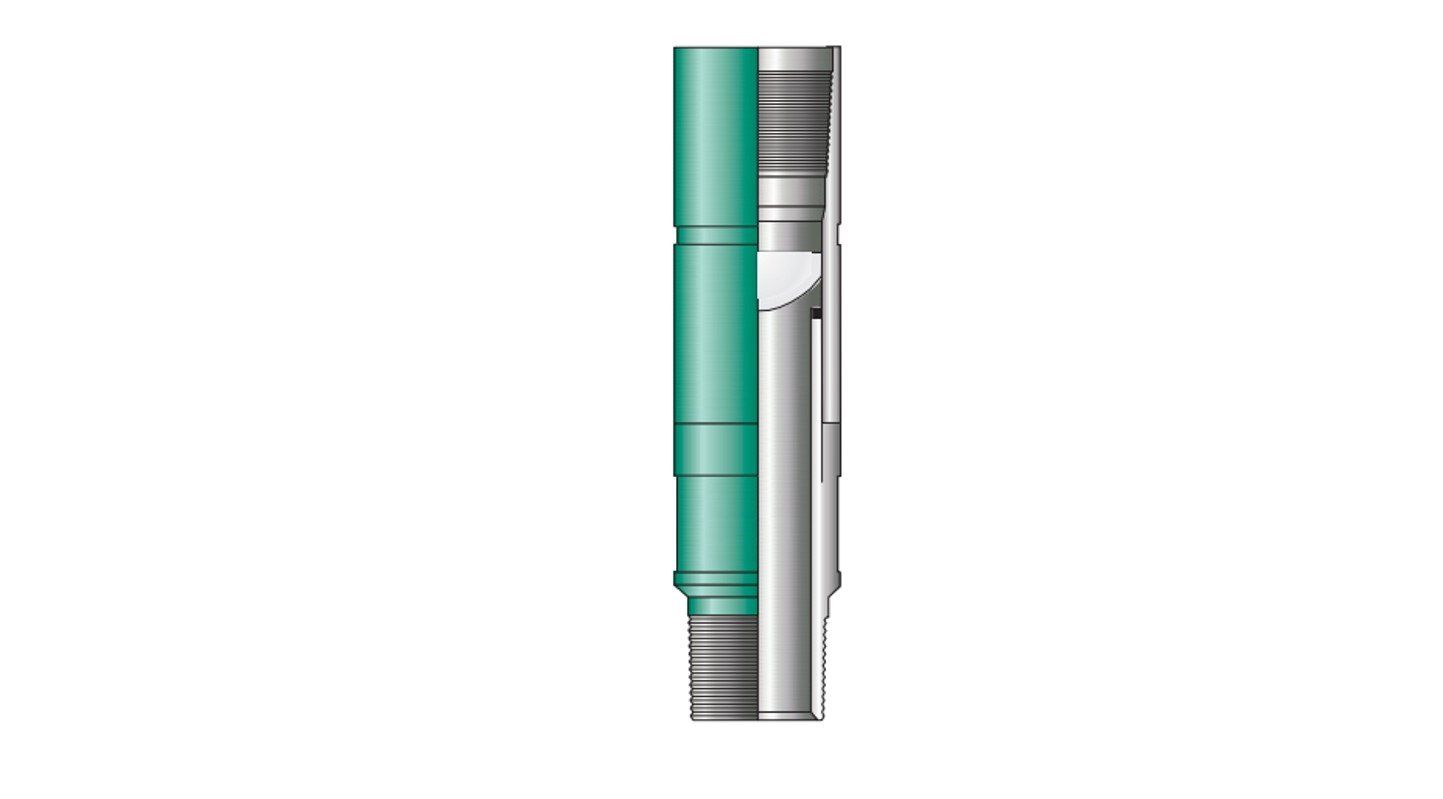

TL ON/OFF TOOL

The TMOT TL On/Off Tool Overshot is the disconnect/connect portion of the tool. The TL Overshot is connected to the tubing string and disconnects from the TL Slick Joint which is connected to the tool string below. The standard overshot incorporates 2 - 4 bonded seals to ensure a reliable seal even after numerous disconnects/connects. These seals can be made out of various materials to ensure compatibility in almost any environment.

The TL On/Off Tool is normally a left hand 1/4 turn at the tool disconnect with an auto-J on. However, a right-hand disconnect option is available The TL On/Off Tool Slick Joint connects to a double grip packer or packer system that does not require tension or compression to maintain a pack-off. The slick joint normally has a landing profile machined into it to serve as a receptacle for various flow control devices.

The TL Overshot / Slick Joint is available in a wide range of materials and both 42 Mpa (6000psi ) and 70 Mpa (10,000psi) differential pressure rating. The TXL On/Off Tool incorporates an extended seal surface to allow for greater versatility when running multi-packer applications. Other than being longer, the TXL On/Off Tool functions and has the same features of the TL On/Off tool.

- PROVEN RELIABLE BONDED SEAL SYSTEM

- AVAILABLE IN A WIDE RANGE OF MATERIALS

- 42mPa (6000psi) & 70 mPa (10,000psi) PRESSURE RATINGS AVAILABLE

- NORMALLY LH RELEASE WITH OPTIONAL RH AVAILABLE

- OPTIONAL THREAD CONNECTIONS AVAILABLE

- LANDING PROFILE NORMALLY IN SLICK JOINT

- THERMAL VERSION AVAILABLE

HYDRAULIC TUBING DRAIN

The TMOT Hydraulic Tubing Drain is used to create a drain port for equalizing fluid levels in the tubing string. TMIs allows the operator to avoid pulling a wet string without perforating or cutting.

The TMOT Tubing Drain can be configured to be used with a plugging device below or can be activated by dropping a ball.

- FIELD ADJUSTABLE OPENING PRESSURE

- UNAFFECTED BY TUBING MOVEMENT OR FLOW RATES

- PROVIDES EQUALIZATION OF TUBING TO ANNULUS

- WIDE RANGE OF MATERIALS AND CONNECTIONS AVAILABLE

TR ROTATIONAL SHEAR SAFETY JOINT

The TMOT TR Rotational Safety Joint provides for emergency release of the tubing string. The TR Rotational Safety Joint uses larger square threads to separate the upper and lower subs with right-hand rotation abandoning any production equipment below.

- AVAILABLE IN MOST COMMON TUBING SIZES

- FULL BORE I.D.

- READILY FIELD ADJUSTABLE SHEAR

- SHEARS BY RH ROTATION

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

Product Line Summary

TP ROTATIONAL SHEAR SAFETY JOINT

The TMOT TR Rotational Safety Joint provides for emergency release of the tubing string. The TR Rotational Safety Joint uses larger square threads to separate the upper and lower subs with right-hand rotation abandoning any production equipment below.

- AVAILABLE IN MOST COMMON TUBING SIZES

- FULL BOREI.D.

- READILY FIELD ADJUSTABLE SHEAR

- SHEARS BY RH ROTATION

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

TQ TORQUE-THRU SHEAR SAFETY JOINT

The Tryon TQ Torque-Thru Shear Safety Joint provides for emergency release of the tubing string. Straight pull separates the tool at a predetermined shear value. In addition, the TQ Torque-Thru Shear Safety Joint allows torque to be transmitted through the tool without affecting the shear screws.

- AVAILABLE IN MOST COMMON TUBING SIZES

- FULL BORE I.D.

- READILY FIELD ADJUSTABLE

- SHEARS BY STRAIGHT PULL

- ALLOWS FOR TORQUE TO BE TRANSMITTED THROUGH WITHOUT AFFECTING THE SHEAR SCREWS

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

BLAST JOINTS

Blast Joints are used to protect the tubing string from the abrasive action of flowing gas or oil when positioned opposite the perforations. Blast Joint may also be used directly below the wellhead to protect from the abrasion of doing a hydraulic fracturing operation down the annulus.

Blast Joints are made from high-quality steel treated to between 28 & 36 RC hardness to ensure maximum abrasion resistance and strength. For H2S service, blast joints are heat-treated to between 18 & 22 RC hardness as per N.A.C.E. specification MR-0175. Other materials are available on advance order if required.

Full tubing I.D. is maintained through the blast joint with the O.D. the same as tubing couplings. As standard, blast joints have API EUE tubing connections, but can be cut with virtually any thread connection required.

- AVAILABLE IN A WIDE RANGE OF SIZES AND CONNECTIONS

- STANDARD AVAILABLE LENGTHS RANGE FROM 0.6M (2FT) TO 3.6M (12FT)

- FULL BORE I.D.

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

PUMP OUT PLUGS

SOLID PUMP OUT PLUG

The Solid Pump-Out Plug is the most commonly used plug and has a solid aluminum expendable end.

BULLNOSE PUMP OUT PLUG

The Bullnose Pump-Out Plug assembly is recommended when running into lines or highly deviated wells

Product Line Summary

PUMP OUT PLUGS

BALL SEAT PUMP OUT PLUG

The Ball Seat Pump-Out Plug assembly allows fluid flow from both directions until a ball is circulated down onto the expendable landing seat or the ball can be run in place allowing the tubing to fill

INLINE PUMP OUT PLUG

The Inline Pump-Out Plug is a commonly used plug and has a solid aluminum expendable end and allows for a perforated pup joint or catcher sub to be attached below to catch the expendable end

TBS SINGLE BURST DISK

The TMOT TBS Single Burst Disk is a field-proven, debris-free knockout plug that is generally used below a packer or in the tailpipe assembly isolating the wellbore below. Coil tubing, slickline, drop bar or sand line can be used to rupture the ceramic disk allowing production up the tubing with no debris interference.

The TBS Single Burst Disk is generally used for well control and/or to set a hydraulic packer or packers.

- ALTERNATIVE TO PROFILE NIPPLE WITH A PLUG

- HIGH PRESSURE RATING - 70 mPa (10,000 PSI) FROM BELOW

- FULL OPENING AND NO DEBRIS LEFT AFTER RUPTURE

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

- AVAILABLE IN STANDARD

TBD DUAL BURST DISK

The TMOT TBD Dual Burst Disk is a field-proven, debris-free knockout plug that is generally used below a packer or in the tailpipe assembly isolating the wellbore below. Coil tubing, slickline, drop bar or sand line can be used to rupture the ceramic disk allowing production up the tubing with no debris interference.

The TBD Dual Burst Disk is generally used for well control and/or to set a hydraulic packer or packers.

ALTERNATIVE TO PROFILE NIPPLE WITH A PLUG

- HIGH PRESSURE RATING - 70 mPa (10,000 PSI) FROM BELOW

- FULL OPENING AND NO DEBRIS LEFT AFTER RUPTURE

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

- AVAILABLE IN STANDARD H2S AND HIGH TEMP SERVICE

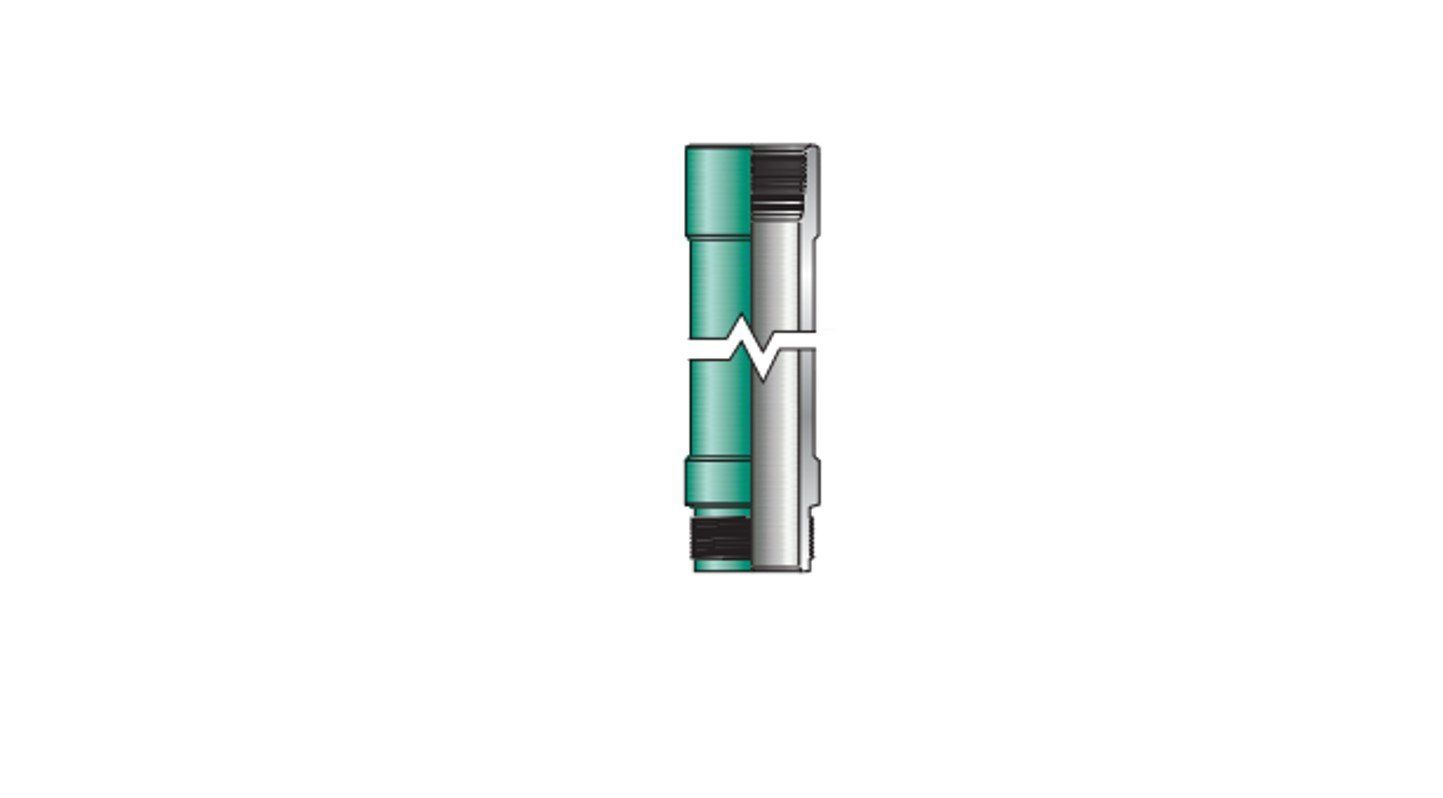

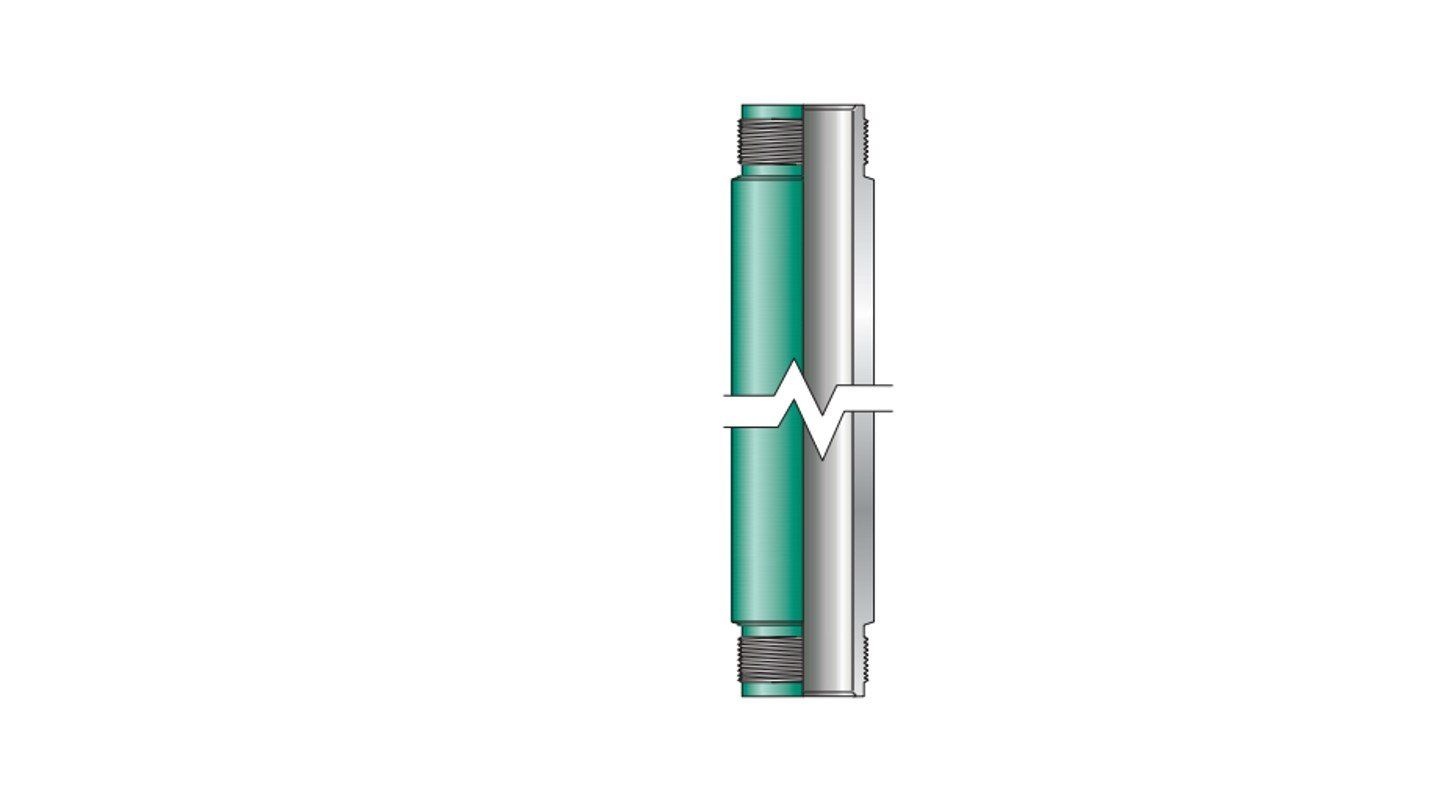

TXJ EXPANSION JOINT

The TMOT TXJ Expansion Joint is placed in the tubing string to allow for pipe contraction or expansion. The TXJ Expansion Joint is generally ran in conjunction with retrievable or permanent type production packers. The TXJ Expansion Joint can be splined in order to allow for left or right-hand rotation when setting or releasing packers, on/off tools, seal assemblies and other downhole equipment that may require rotation.

The TXJ has a proven stacked 'vee' seal design that can be customized to suit almost any environment as can the expansion joint be ordered to accommodate different length requirements, materials, and connections as required.

- AVAILABLE IN A WIDE RANGE OF MATERIALS AND CONNECTIONS

- STANDARD LENGTHS RANGE FROM 0.6M (2FT) T0 3M (10FT)

- FULL BORE I.D.

- PROVEN 'VEE' SEAL DESIGN STACK

- THERMAL VERSION AVAILABLE